Membrane switches form a special category of electrical switches (devices used for turning circuits on and off). They may be defined as momentary switch devices in which at least one contact consists of a flexible substance or is located on a flexible substrate. Marked most of the time by graphically complex user interfaces and multiple flexible layers, membrane switches are called membrane keyboards or membrane keypads at times. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At Telamco, Inc., we specialize in the design and manufacturing of high-quality membrane switches, providing our clients with robust solutions that meet their diverse needs across a variety of industries. Our products are crafted with precision to deliver durability, reliability, and exceptional performance in environments where control and durability are paramount.

At Cole Graphic Solutions, we specialize in providing high-quality membrane switches designed to meet the unique needs of a variety of industries. With a commitment to excellence, we offer custom solutions that are built to deliver exceptional performance, durability, and precision.

More Membrane Switch Manufacturers

Membrane switches, a crucial component in modern human-machine interfaces, serve as user-equipment interface utilities that allow seamless communication between users and electronic devices. Unlike traditional mechanical switches—composed chiefly of plastic components and copper—membrane switches feature a more advanced structure comprising a printed circuit and a flexible substrate. Their streamlined design, combined with robust performance and reliability, has made them an increasingly popular choice across industries seeking high-performance control solutions for electronic products.

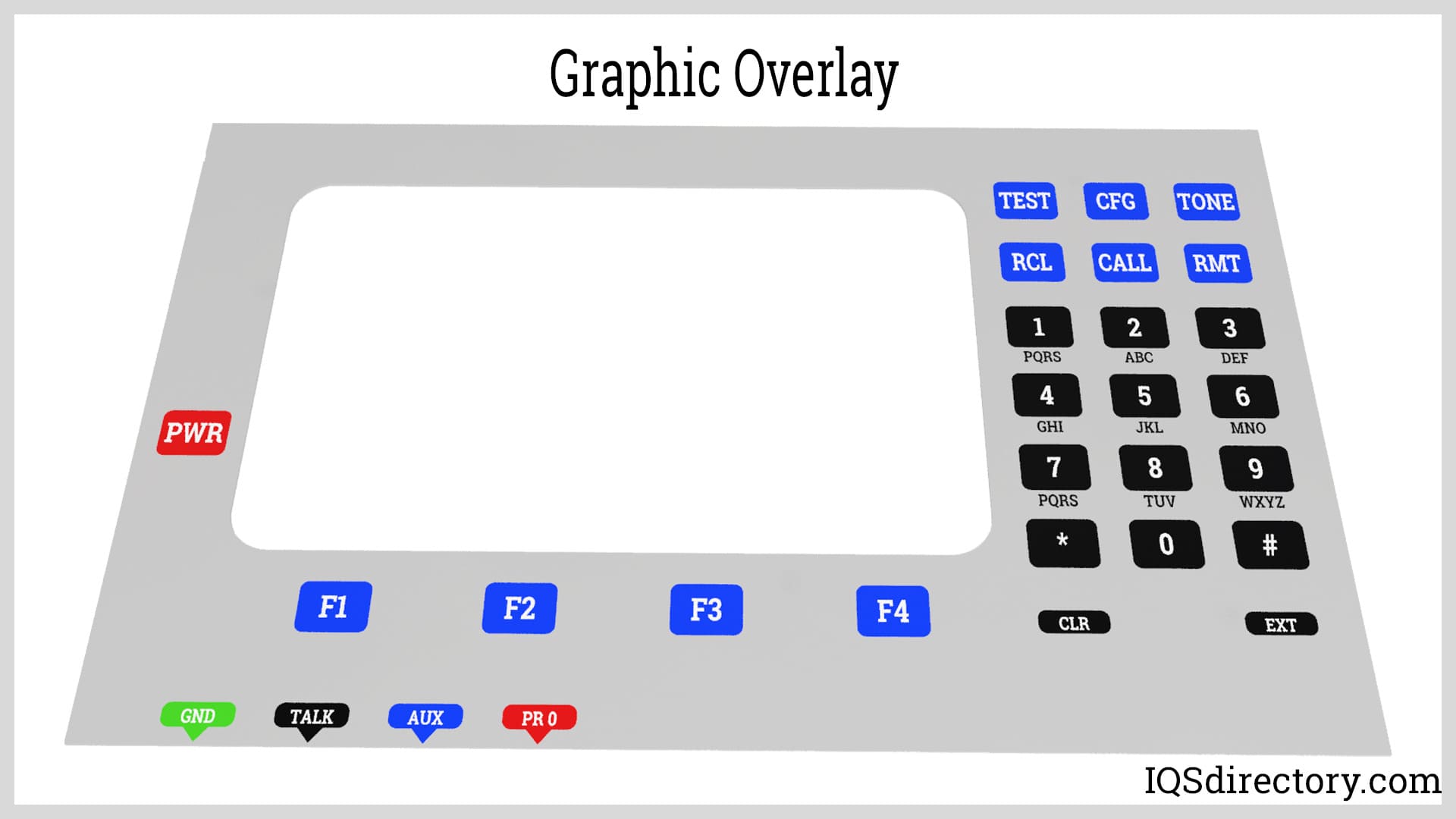

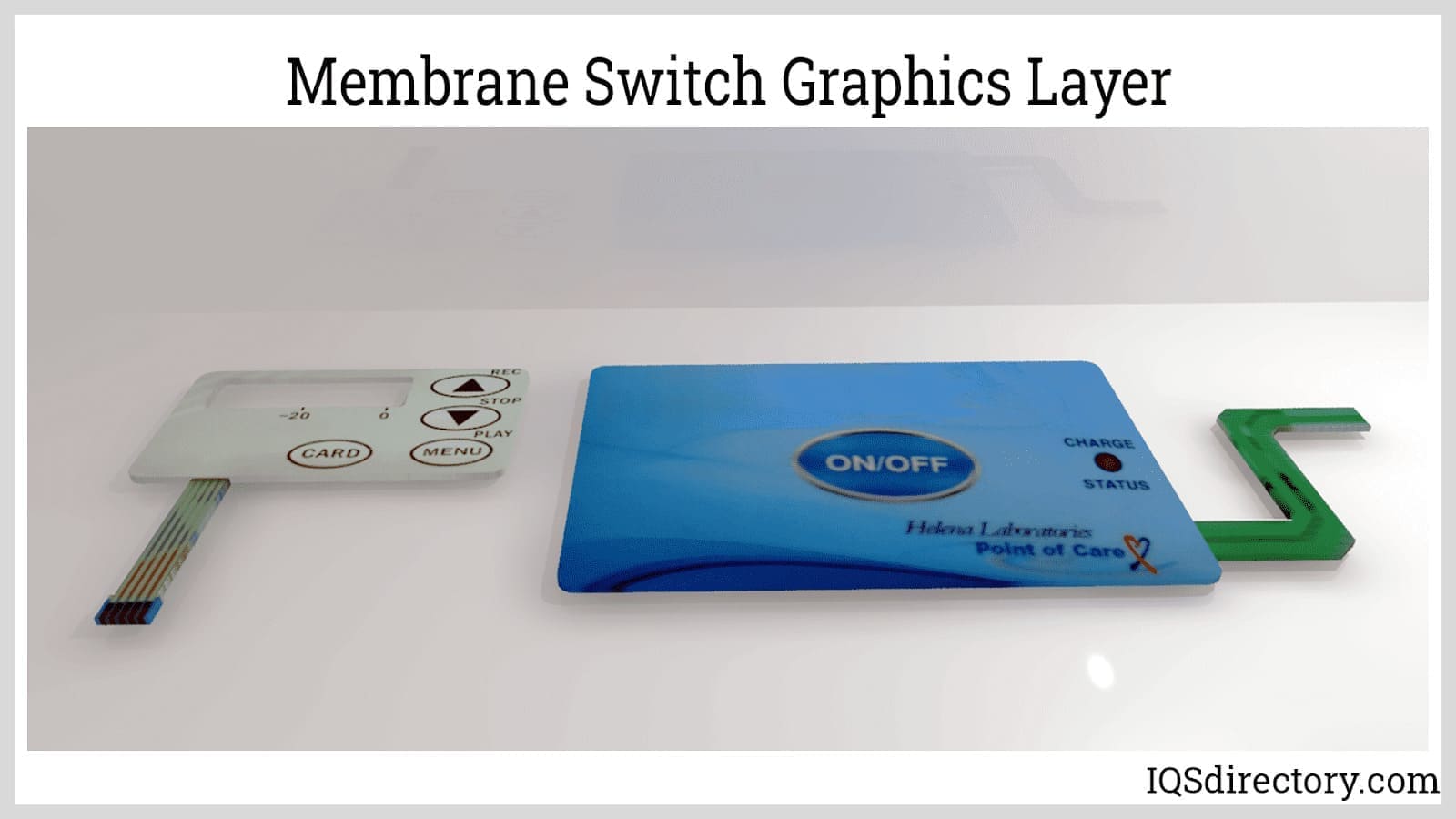

A membrane switch, often referred to as a touch switch, is a sophisticated multi-layered device that acts as an electrical switch, enabling users to turn a device on or off or control its various functions. These switches employ printed circuits on flexible films, distinguishing them from mechanical switches constructed using copper and polymers. The manufacturing process typically involves the deposition of conductive silver or carbon ink onto heat-stabilized polyester (PET) film. The topmost layer—the overlay—serves as the switch’s user interface, displaying graphics, icons, or text relevant to the device’s operations. These overlays, or “graphic overlay films,” are constructed from thin, flexible materials, lending the switch its name and unique tactile properties.

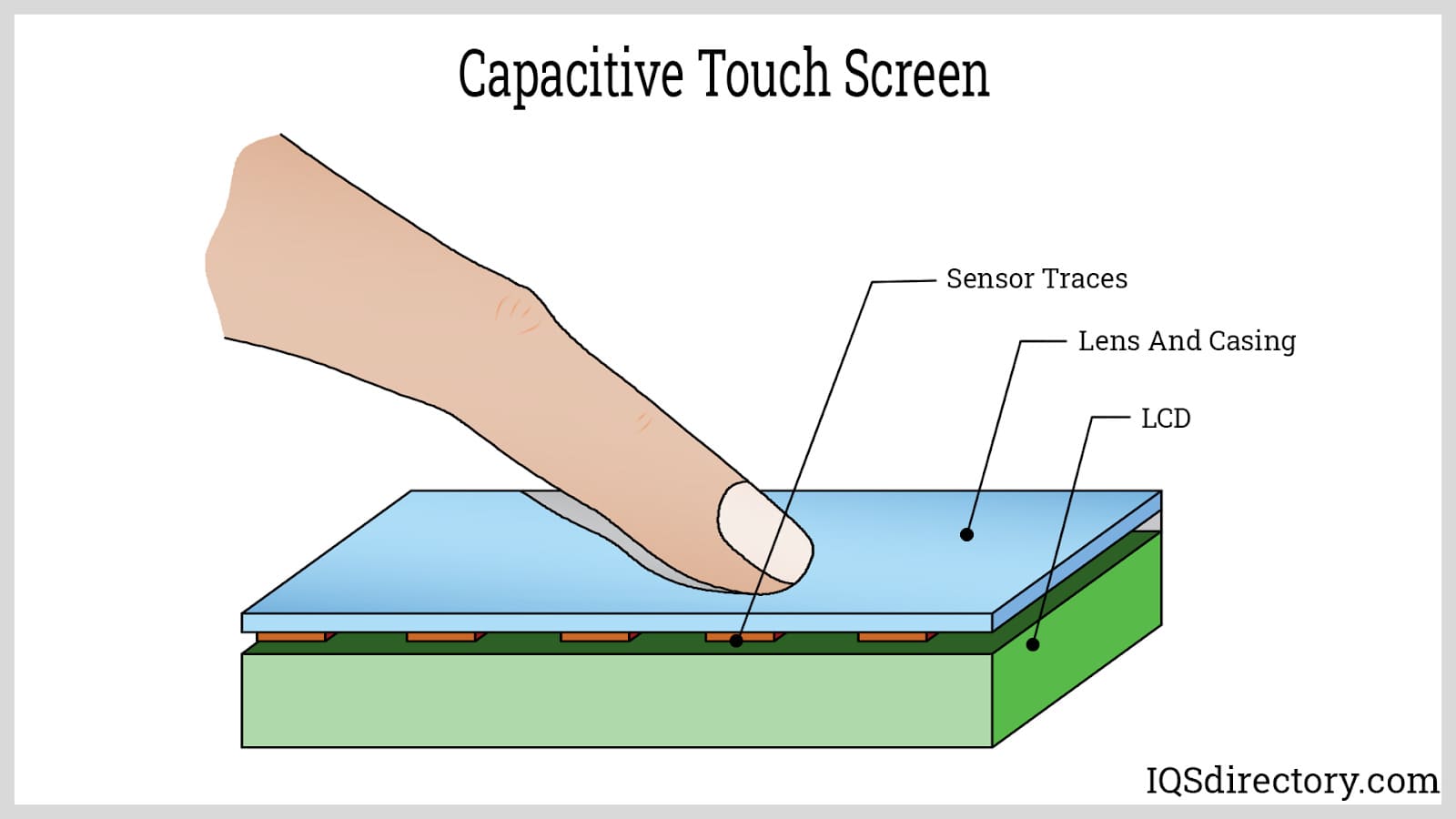

Membrane switches are renowned for their low profile, sealing capability, and ease of cleaning, making them ideal for environments where hygiene and durability are critical. Their adaptability allows seamless integration with other control systems, such as keypads, capacitive touch screens, and LED lighting arrays. Membrane switches can be engineered into complex assemblies like membrane keyboards and multi-function switch panels, as seen in mobile phones, medical devices, and industrial equipment. Depending on their specific design and application, they may also be referred to as membrane keyboards, membrane keypads, or even touch-sensitive panels.

How Membrane Switches Work

The functional principle of a membrane switch is rooted in its layered construction. Electrical contacts are strategically placed across the various film layers, or “membranes,” within the switch assembly. In their default, open state, membrane switches maintain an incomplete circuit, preventing current flow and keeping the device in an “off” or inactive status. When the user applies pressure to a designated button area on the graphic overlay, the layers are pressed together, bringing conductive traces into contact and closing the circuit—thus activating the desired function.

This pressure-activated mechanism enables membrane switches to deliver reliable, consistent user input across thousands, or even millions, of actuations. Depending on the intended use, actuation force, tactile feedback, and overall switch sensitivity can be finely tuned by choosing appropriate materials, dome structures, and overlay thicknesses.

Membrane Switch Parts

At a fundamental level, membrane switches require a minimum of two circuit layers to complete an electrical connection. However, most commercial membrane switches feature three to seven carefully engineered layers, each fulfilling a specialized function to enhance durability, responsiveness, and performance. The primary layers include:

- Circuit Layer: The electrically conductive pathways necessary for completing the circuit reside in this layer, typically positioned at the bottom of the assembly. Depending on the design, the circuit layer can take multiple forms:

- Membrane Circuit Layer: The flexible upper circuit layer housing one pole of the switch circuit.

- Static Circuit Layer: The rigid lower circuit layer, often featuring a durable backing and carrying the other pole of the circuit.

Circuit patterns are created using screen-printed conductive ink (such as silver or carbon) on polymer films. For more robust applications, printed circuit board (PCB) membrane switches use rigid boards (e.g., FR4, ITO, or PET) for added structural integrity and soldering capability. Flex Circuit membrane switches utilize flexible substrates like polyester (PET) or polyimide (Kapton), making them suitable for curved or irregular surfaces. Advanced types, such as Silver Flex membrane switches or Copper Flex membrane switches, offer enhanced conductivity and reliability for demanding environments.

- Graphic Overlay: The user-facing top layer, or “graphic overlay,” is where interface elements like buttons, windows, and icons are displayed. Overlays are typically constructed from polyester or polycarbonate films, chosen for their chemical resistance, durability, and printability. Advanced overlays can be embossed, screen-printed, or digitally printed with high-resolution graphics, facilitating intuitive user interaction and brand customization. For extreme environments, overlays can be engineered for increased heat, abrasion, or impact resistance. Explore graphic overlay options for your application.

- Adhesive Layers: Pressure-sensitive adhesive layers bond the upper and lower layers together. The overlay adhesive secures the graphic overlay to the circuit, while the rear adhesive attaches the assembly to a rigid backing or mounting panel. These adhesives create a hermetic seal, protecting internal circuits from dust, moisture, and contaminants. In high-reliability environments, such as medical or food processing, this feature is vital for sustaining performance and minimizing maintenance.

- Dome Layer (optional): For tactile feedback, a dome layer—often made of stainless steel or polyester domes—is included. When pressed, these domes collapse, providing a distinct tactile response and audible click, which assures users of successful actuation. Learn more about dome switch options.

- Spacer Layer: This layer separates the upper and lower circuit layers, preventing inadvertent contact. It typically features die-cut openings (“switch cavities”) beneath each button to allow actuation only when intended.

- Rigid Backing (optional): For added stability or ease of mounting, membrane switches may be adhered to aluminum, stainless steel, or plastic panels—referred to as membrane switch panels. This facilitates integration into control panels or enclosures.

Thanks to this layered design, membrane switches eliminate crevices where dirt and liquids could infiltrate, offering exceptional protection to sensitive electronics and extending product lifespan. This construction also enhances the tactile experience, particularly in switches equipped with metal or plastic domes beneath the overlay.

Specific Types of Membrane Switches

Membrane switch technology is highly versatile, accommodating a broad spectrum of designs tailored to unique industry requirements. From simple tactile switches used in basic lighting controls to sophisticated membrane keyboards found in computing and medical diagnostics, the range of applications is extensive:

- Packaged Membrane Switches: These basic switches feature a membrane and static layer within an enclosure, typically soldered onto a PCB for compact, cost-effective solutions in consumer electronics.

- Transparent Membrane Switches: Also known as touch screens, these advanced interfaces combine transparency with pressure or capacitive detection, making them ideal for handheld devices, automotive controls, and interactive kiosks.

- Tactile Membrane Switches: These switches incorporate metal or polyester domes, offering users distinct tactile, audible, or visual feedback upon actuation. They are preferred in environments where positive feedback is crucial, such as industrial controls or medical equipment.

- Non-Tactile Membrane Switches: Utilizing conductive ink rather than domes, non-tactile membrane switches offer silent actuation with feedback provided via LEDs or display indicators. These are commonly chosen for environments where minimal noise and rapid actuation are desired.

- Backlit Membrane Switches: For applications requiring visibility in low-light conditions, membrane switches can be backlit using various technologies:

- LED Backlighting: Surface-mount or layer-mounted LEDs provide bright, focused indicator lights. While cost-effective, they are best for selective illumination rather than uniform panel lighting. Want to understand when to use LED backlighting? Read our guide on LED membrane switch illumination.

- Optical Fiber: Fiber optic cloth creates evenly distributed panel lighting, unaffected by temperature or humidity extremes. It boasts long operational life (10,000 to 100,000 hours) and is ideal for critical applications in aerospace, defense, and transportation.

- Electroluminescent (EL) Lamps: EL layers are ultra-thin, flexible, and capable of custom shapes. They offer design flexibility and are often employed in mobile devices, dashboards, and medical equipment, though their brightness diminishes after 3,000–8,000 hours.

- EMI/RFI Shielded Membrane Switches: In environments exposed to electromagnetic interference or radio frequencies, membrane switches can be equipped with EMI/RFI shielding layers, grounding tabs, or conductive adhesives to protect sensitive circuitry and ensure reliable operation.

Looking to compare tactile versus non-tactile membrane switch options for your control panel? Explore our detailed comparison to find the right fit for your application.

Advantages of Membrane Switches

Membrane switches offer a host of advantages over mechanical or capacitive alternatives, making them the preferred choice for a wide array of electronic control interfaces:

- Affordability: Fewer materials, streamlined manufacturing, and efficient assembly processes reduce both production and maintenance costs.

- Durability: Layered, adhesive-bound construction provides resistance to moisture, dust, and chemicals, making switches easy to clean and suitable for harsh environments.

- Space Efficiency: Thin, low-profile designs enable integration into compact or portable devices, maximizing space in crowded control panels.

- Customization: Flexible manufacturing allows for tailored shapes, sizes, colors, and graphics to match branding or ergonomic requirements. Integration of LEDs, fiber optics, or EL panels further enhances functionality.

- Reliability: With no moving mechanical parts to wear out, membrane switches deliver millions of actuations with consistent performance—critical for mission-critical or high-traffic applications.

- Hygiene: Seamless, sealed surfaces are easy to sanitize, making membrane switches the standard for medical, food processing, and laboratory equipment.

- Versatility: Compatible with a wide range of technologies, from simple indicator lights to complex capacitive touch displays and wireless control modules.

Curious about how membrane switches can reduce downtime and maintenance costs in your facility? Learn about long-term savings with membrane technology.

Membrane Switch Applications

The robust performance and adaptable design of membrane switches have secured their position as the interface of choice in diverse markets, including:

- Aerospace: Cockpit control panels, avionics, and navigation systems require reliable, lightweight, and EMI/RFI-shielded membrane switches.

- Medical Devices: Used in handheld diagnostic equipment, hospital bed controls, infusion pumps, and imaging systems, where hygiene and reliability are paramount.

- Industrial Controls: Keypads and operator interfaces for factory automation, robotics, and process controls benefit from rugged, spill-resistant membrane switches.

- Consumer Electronics: Remote controls, microwave panels, calculators, and home appliances depend on membrane switches for intuitive user input.

- Security Systems: Access control keypads and alarm system panels utilize membrane switches for secure, tamper-resistant operation.

- Automotive: Dashboard controls, climate control panels, and infotainment systems integrate membrane switches for reliable, backlit, and ergonomic interfaces.

- Gaming and Entertainment: Slot machines, arcade games, and interactive kiosks leverage customizable, illuminated membrane switch technology to enhance user engagement.

Wondering if membrane switches are suitable for your next product design? Browse real-world membrane switch applications or request a custom quote for your specific requirements.

Membrane Switch Circuits: FPC or PET?

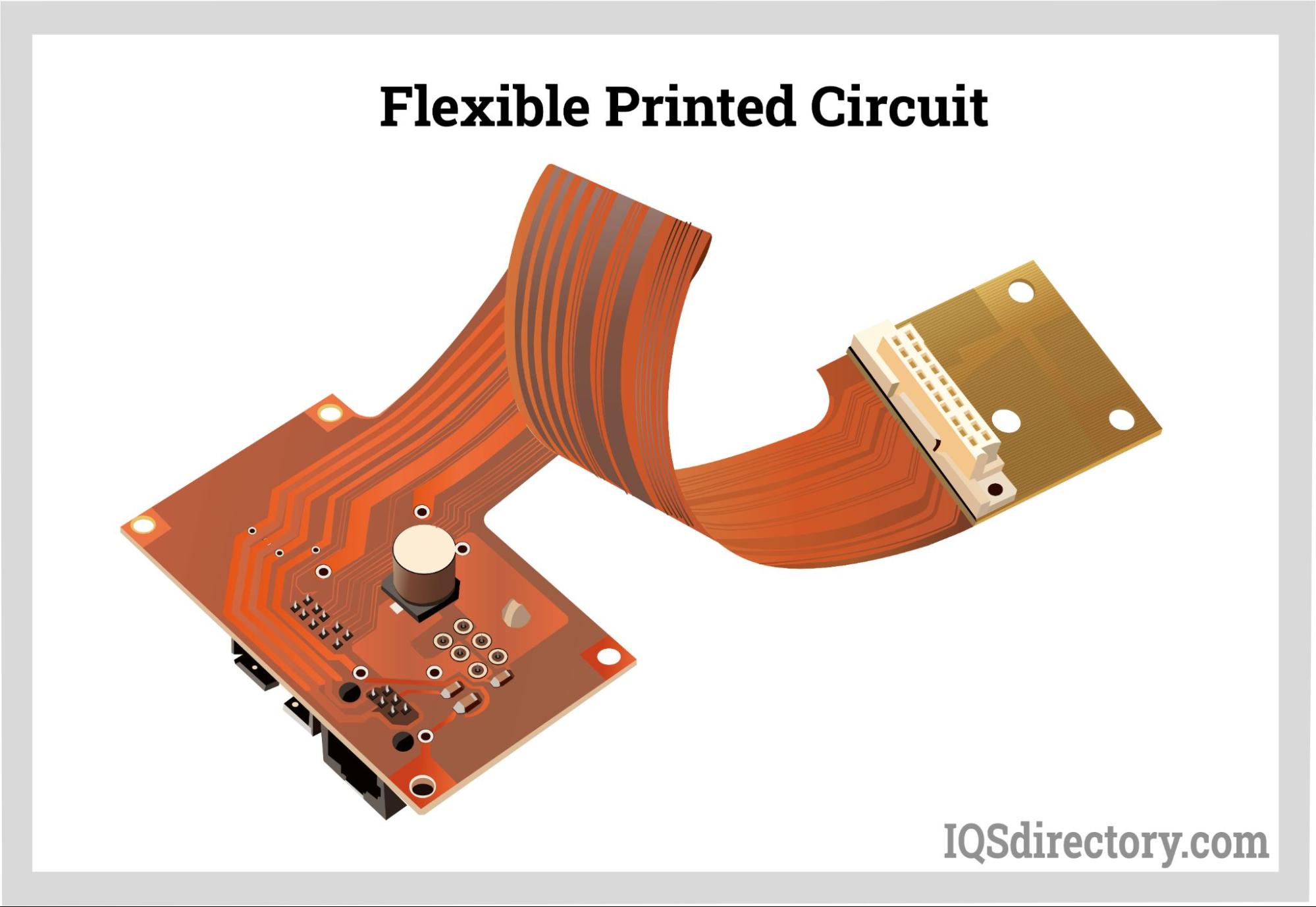

When selecting a membrane switch, one of the most important considerations is the type of circuit technology employed. The two primary circuit types are PET (polyethylene terephthalate) and FPC (flexible printed circuit), each with distinct features, advantages, and trade-offs:

- PET Circuits: Most common in cost-sensitive, standard applications. PET circuits use screen-printed silver or carbon ink on polyester film to form conductive pathways. Surface-mount components are attached using conductive epoxy paste. While PET circuits are economical, their epoxy bonds are less robust in high-vibration or extreme-temperature environments.

- FPC Circuits: Offer enhanced durability and reliability. FPC circuits utilize copper traces on polyimide or polyester substrates, allowing fine pitch, complex layouts, and higher current capacity. Components are soldered for maximum bond strength—ideal for demanding industrial, aerospace, and automotive applications.

Key considerations when choosing PET or FPC circuits include:

- Component Density: FPC circuits accommodate more components in smaller areas due to finer trace widths, simplifying complex layouts and enabling miniaturization without sacrificing performance.

- Electrical Performance: Copper FPC circuits have up to 15 times lower resistance than silver-ink PET circuits, making them preferable for applications requiring minimal voltage loss or higher current loads.

- Environmental Resistance: FPC circuits, with their soldered joints and copper conductors, outperform PET in environments subject to vibration, extreme temperatures, or moisture.

- Manufacturing Process: PET circuits are screen-printed, while FPC circuits are manufactured through precise etching. Both provide rapid production, but FPC offers superior high-density interconnect capabilities.

- Cost: PET circuits are generally more affordable, especially for large, low-complexity designs. FPC carries a higher material and processing cost, but the price premium is often justified by enhanced durability and feature density in advanced applications.

Still unsure which circuit technology is best for your membrane switch project? Compare FPC vs. PET circuits in our expert guide or consult a membrane switch engineer for personalized recommendations.

Membrane Switch Considerations

The quality and long-term reliability of a membrane switch are highly dependent on the design, materials, and manufacturing processes used for each individual layer. To ensure robust performance—especially in critical or regulated environments—customers should partner with experienced membrane switch manufacturers who maintain rigorous quality controls, such as cleanroom assembly and advanced inspection techniques.

When evaluating membrane switch suppliers, consider the following decision factors:

- Manufacturing Expertise: Choose companies with deep experience in designing membrane switches for your specific industry, whether it’s medical, aerospace, automotive, or industrial automation.

- Product Variety: Look for suppliers offering a broad range of membrane switches, from basic keypads to advanced, integrated switch panels with backlighting, touch sensors, and wireless modules.

- Design Support: Reliable suppliers provide engineering guidance to help specify the optimal combination of materials, circuits, overlays, and feedback mechanisms for your application.

- Prototyping and Testing: Ensure the manufacturer offers prototyping, environmental testing, and quality assurance to verify switch performance before full-scale production.

- Customization Capabilities: Consider the provider’s ability to supply custom graphics, shapes, mounting options, and integration with displays, sensors, or enclosures.

- Regulatory Compliance: For medical, aerospace, or safety-critical uses, ensure your membrane switches are manufactured in accordance with relevant standards (e.g., ISO 13485, IPC standards, UL certification).

When should you choose a tactile versus non-tactile switch? Non-tactile switches are often favored for their silent operation, broad customization potential, and lower cost. However, tactile switches are indispensable in applications demanding physical feedback—such as industrial machinery, medical diagnostics, or security systems. Remember that overlay thickness, dome type, and actuation force all influence both tactile feedback and durability, so a balanced approach is key to optimal performance.

Interested in learning more about membrane switch engineering? Contact a specialist to discuss your project’s unique requirements.

Frequently Asked Questions About Membrane Switches

- What are the most common applications for membrane switches?

- How do tactile and non-tactile membrane switches differ?

- Should I choose a PET or FPC circuit for my membrane switch?

- When is LED backlighting recommended for membrane switch panels?

- How do membrane switches reduce operational costs?

What are the most common applications for membrane switches?

Membrane switches are widely used in medical devices, industrial machinery, aerospace controls, consumer electronics, security systems, and automotive interiors due to their durability, low profile, and ease of cleaning. Their ability to integrate custom graphics, lighting, and tactile feedback makes them highly adaptable for a variety of user interface solutions.

How do tactile and non-tactile membrane switches differ?

Tactile membrane switches include metal or polyester domes that provide a physical “click” when pressed, enabling users to feel and sometimes hear each actuation. Non-tactile switches use conductive ink to register input, offering silent operation and visual/audible indicators as feedback. The choice depends on user preference, operational environment, and application requirements.

Should I choose a PET or FPC circuit for my membrane switch?

PET circuits are cost-effective and adequate for most standard applications, while FPC circuits offer higher reliability, lower resistance, and support for higher component density—ideal for demanding environments or complex designs. Evaluate your application’s space constraints, performance needs, operating environment, and budget when making your selection.

When is LED backlighting recommended for membrane switch panels?

LED backlighting is best for applications requiring selective illumination, such as indicator lights or highlighting specific buttons. For uniform panel lighting, optical fiber or EL lamps may be more suitable. Consider LED backlighting if you need energy efficiency, long life, and precise location-specific illumination.

How do membrane switches reduce operational costs?

Membrane switches lower overall costs through reduced material use, streamlined assembly, and minimal maintenance requirements. Their sealed, flat surfaces resist contamination and wear, minimizing downtime and replacement frequency compared to mechanical switches. Customization and integration capabilities also reduce the need for additional components or interfaces, offering further cost savings.

Ready to take the next step in your membrane switch project? Request a quote from leading membrane switch manufacturers or explore our comprehensive design resources to ensure your application’s success.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services