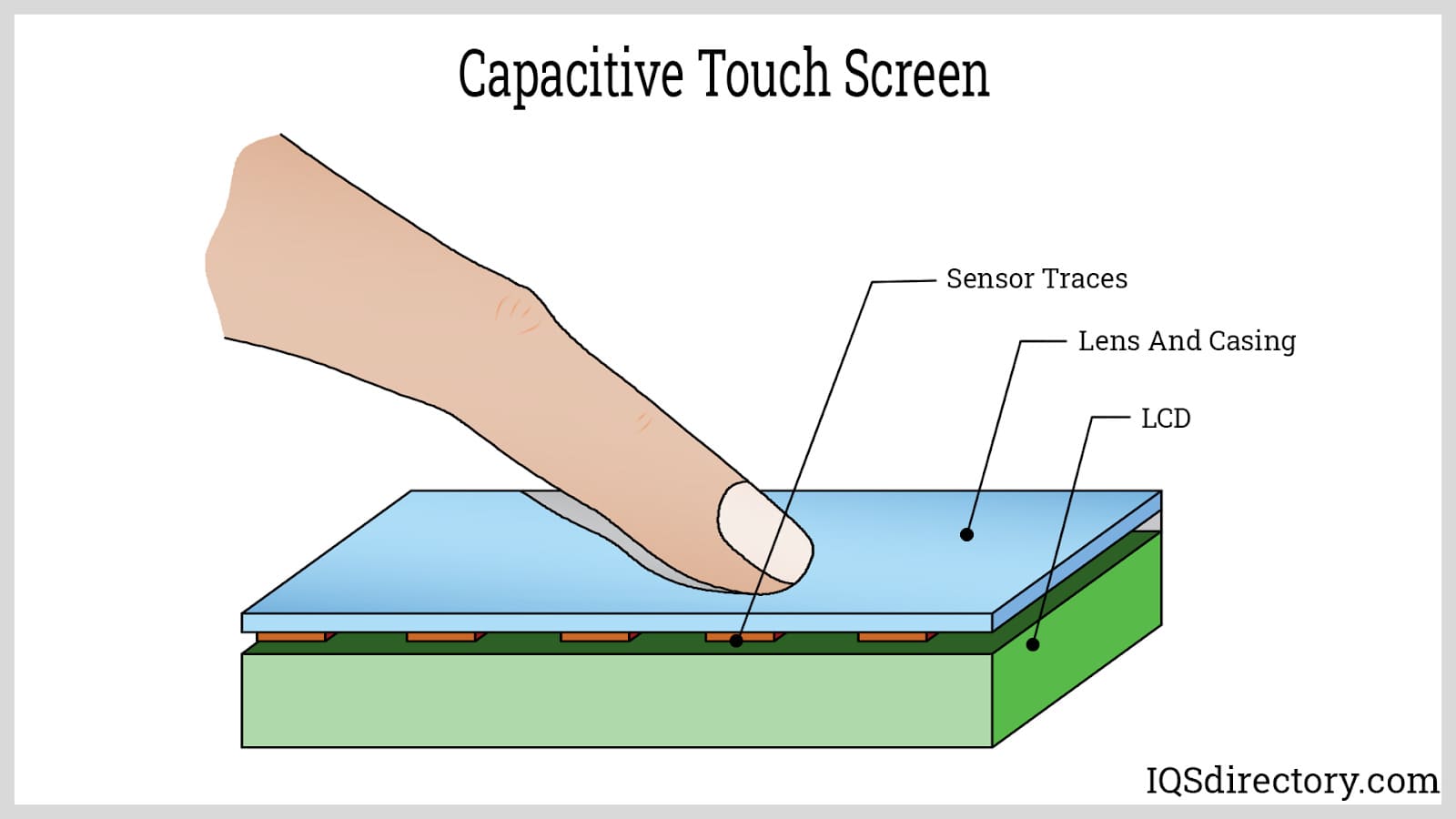

A capacitive switch is an electronic capacitor that detects changes in capacitance values as a conductive object, such as your finger, approaches the sensing area. The change in that value is registered and interpreted as a switch activation. A capacitive membrane switch is a touch sensor that activates when the user makes contact with the sensor. The membrane switch employs capacitive sensing technology to perform traditional membrane switch functions with a light touch. Capacitive touch membrane switches provide excellent design flexibility, durability, and a modern appearance. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At Telamco, Inc., we specialize in the design and manufacturing of high-quality membrane switches, providing our clients with robust solutions that meet their diverse needs across a variety of industries. Our products are crafted with precision to deliver durability, reliability, and exceptional performance in environments where control and durability are paramount.

At Cole Graphic Solutions, we specialize in providing high-quality membrane switches designed to meet the unique needs of a variety of industries. With a commitment to excellence, we offer custom solutions that are built to deliver exceptional performance, durability, and precision.

More Capacitive Switch Manufacturers

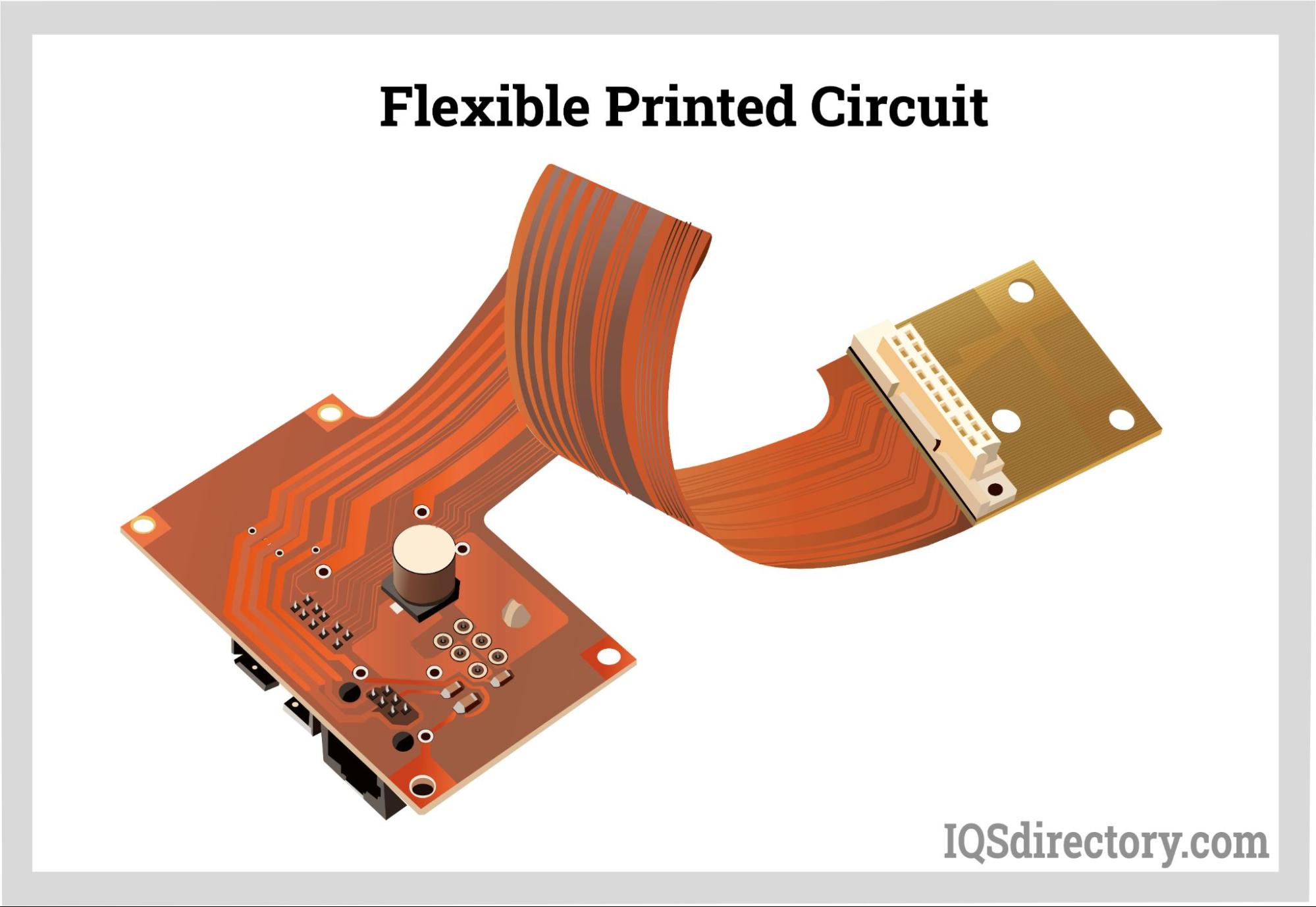

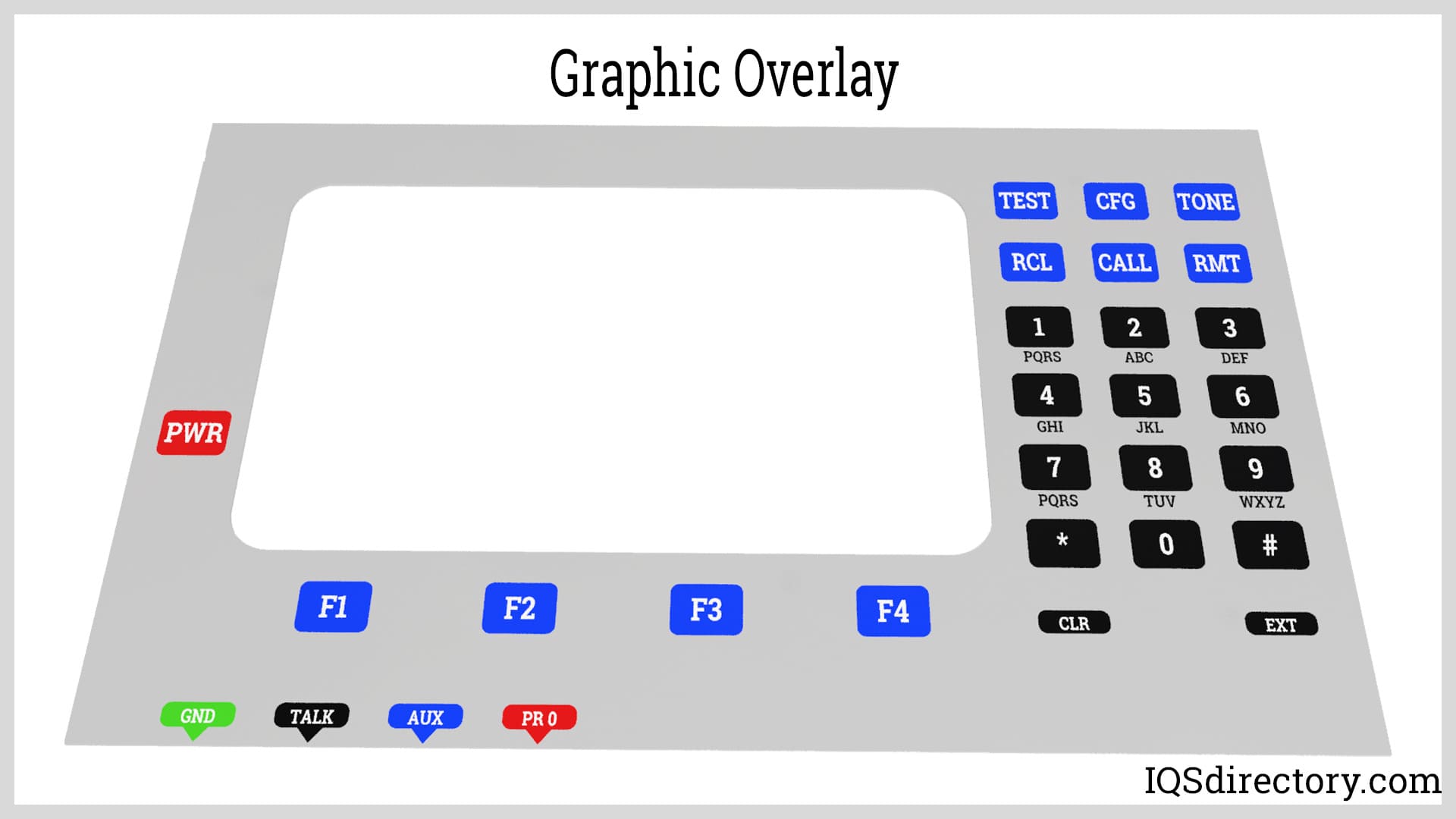

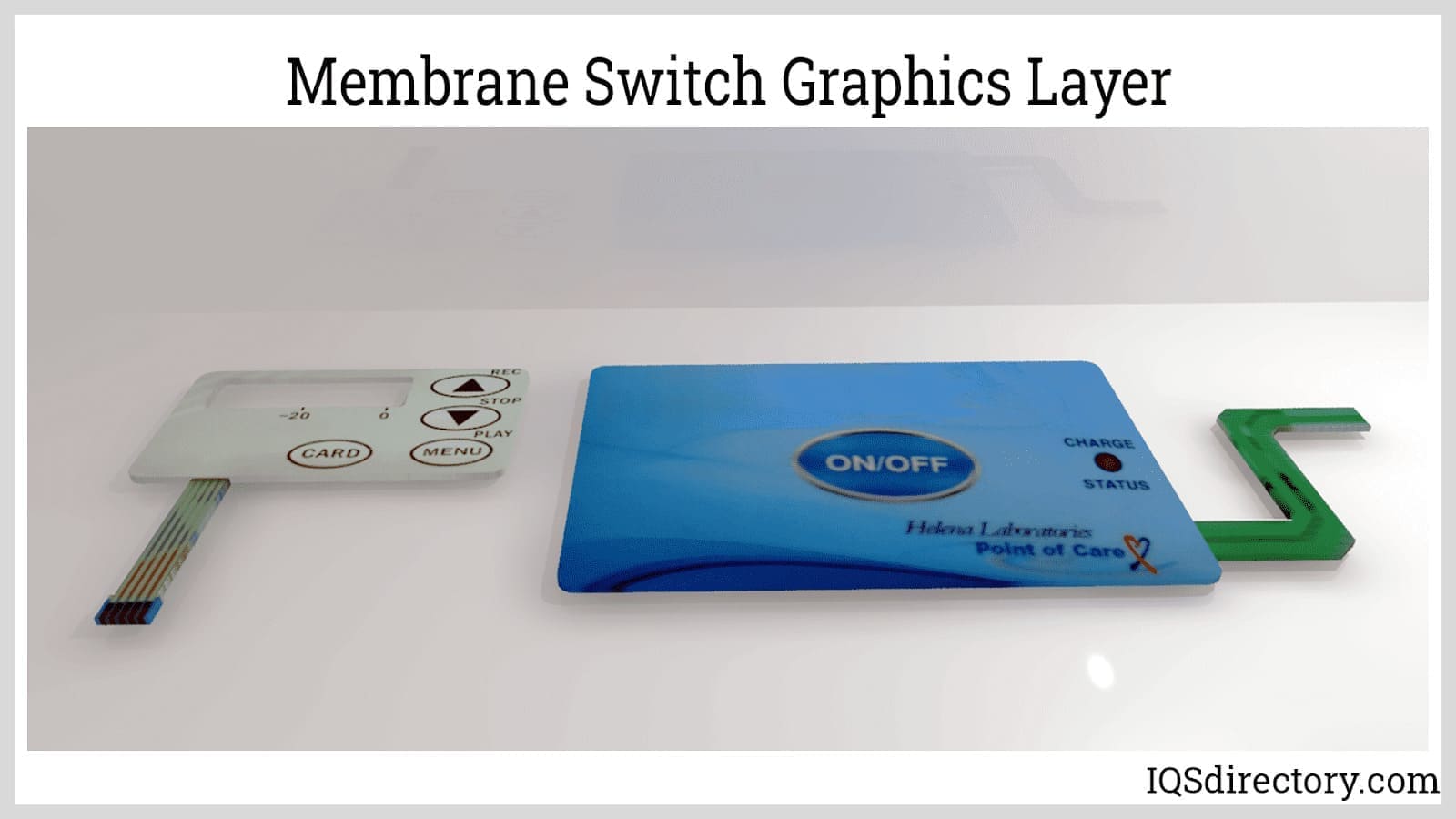

The graphic overlay, circuit, and backer are the three basic components that make up a capacitive switch. Membrane switches of this type use conductive carbon-printed circuitry to generate an electrical field. Most buttons are composed of acrylic panels or injection parts with a backlight display feature and have a nice appearance. Because capacitive keypads have a fashionable appearance and a long service life, they are useful in many applications, including smart home appliances, automobiles, mobile phone communication, medical instruments, and toys.

How Does a Capacitor Switch Work?

When switches are opened and closed, it transfers charge into and out of a capacitor. Non-overlapping signals are typically used to control the switches, also known as “break before make” switching. All switches are open for a very brief period during the switching transitions. There is induction capacitance between any two conductive objects. A key, specifically a solder pad, can also be an induction capacitance with the ground. Under the assumption that the surrounding environment remains constant, the induction capacitance has a small fixed value.

When human fingers are near the touch button, the inductive capacitance formed by human fingers and the ground increases the value of the total inductive capacitance. When a capacitive touch key IC detects a key's inductive capacitance value has changed, it generates a signal. Because the capacitive touch key lacks a mechanical structure, all detection is based on a small change in the electric quantity, making it more susceptible to all types of interference. As a result, the sensor's design and touch IC selection are critical.

How are They Made?

Topflight capacitive touch switches can be made of polyester or other film materials, giving the designer a lot of leeway in graphic solutions and backlighting with a lot of impact and effect. They come complete with the sensor circuit, decorative graphics, and touch surface of your choice. Some capacitive switches are designed with adjustable surface sensitivity, allowing the device they support to be used with or without gloves.

Adjustable surface sensing is especially appealing in colder climates or when an operator must wear gloves for protection. Because capacitive switches operate through sense, they lack mechanical components, which eliminates the possibility of mechanical failure.

Applications of Capacitive Switches

Capacitive switches can be applied to several uses, including the following:

- Medical devices

- Portable devices like phones, laptops, and tablets use capacitive switches in their touch operation

- Appliances

- Consumer electronics

- Personal computers

- Gaming

- Hospitality

- Industrial

- Kiosks

Capacitive switches are used in many industries, including aerospace, defense, industrial, medical, telecommunications, data/communications, and consumer electronics. They frequently function as buttons, sliders, touch pads, touch screens, and proximity settings as interface types. Wireless handsets, PC peripherals, LCD monitors, TVs, laptops, digital cameras, and kiosks are some examples of where they can be found.

Advantages of Capacitive Touch Membrane Switches

- Elegant appearance

- Durability and toughness

- Easy maintenance

- Flexible customization

- Light touch control

- Designs for scrolling and sliders

- Capability for multiple touches

- Design of a curved interface

- Function and communication interface flexibility

- Affordable backlighting alternatives

- Long service life; the key usually has a life of 5-10 years and is not limited by the use of time.

- Water-immune and dustproof solutions

- Can incorporate haptic feedback

- Line noise elimination

- Extremely fast touch response -160 milliseconds

- Very low current requirements

Disadvantages of a Capacitive Switch

- They are sensitive to temperature.

- It cannot interface with a non-conductive object.

- Low-finished product qualification rate

- Sensitivity to ambient electromagnetic interference

- High design complexity

- The interaction of electronic components and chips must be noticed.

Conclusion

A capacitive switch is an electronic capacitor that detects changes in capacitance values as a conductive object, such as your finger, approaches the sensing area. The change in that value is registered and interpreted as a switch activation. Environmental conditions, mechanical requirements, electrical requirements, appearance, and certification are all important factors when designing a capacitive switch.

Capacitive switches have grown in popularity as an alternative to mechanical switches, elastomer keypads, membrane switches, and other input device options in recent years. Capacitive switches offer exciting possibilities for your user interface, with no mechanical parts to wear out, intricate backlighting options, and a slender profile that can be applied to curved surfaces.

Choosing the Proper Capacitive Switch Manufacturer

To ensure you have the most beneficial outcome when purchasing capacitive switches from a capacitive switch manufacturer, it is important to compare several companies using our directory of capacitive switch manufacturers. Each capacitive switch manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each capacitive switch business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple capacitive switch companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services