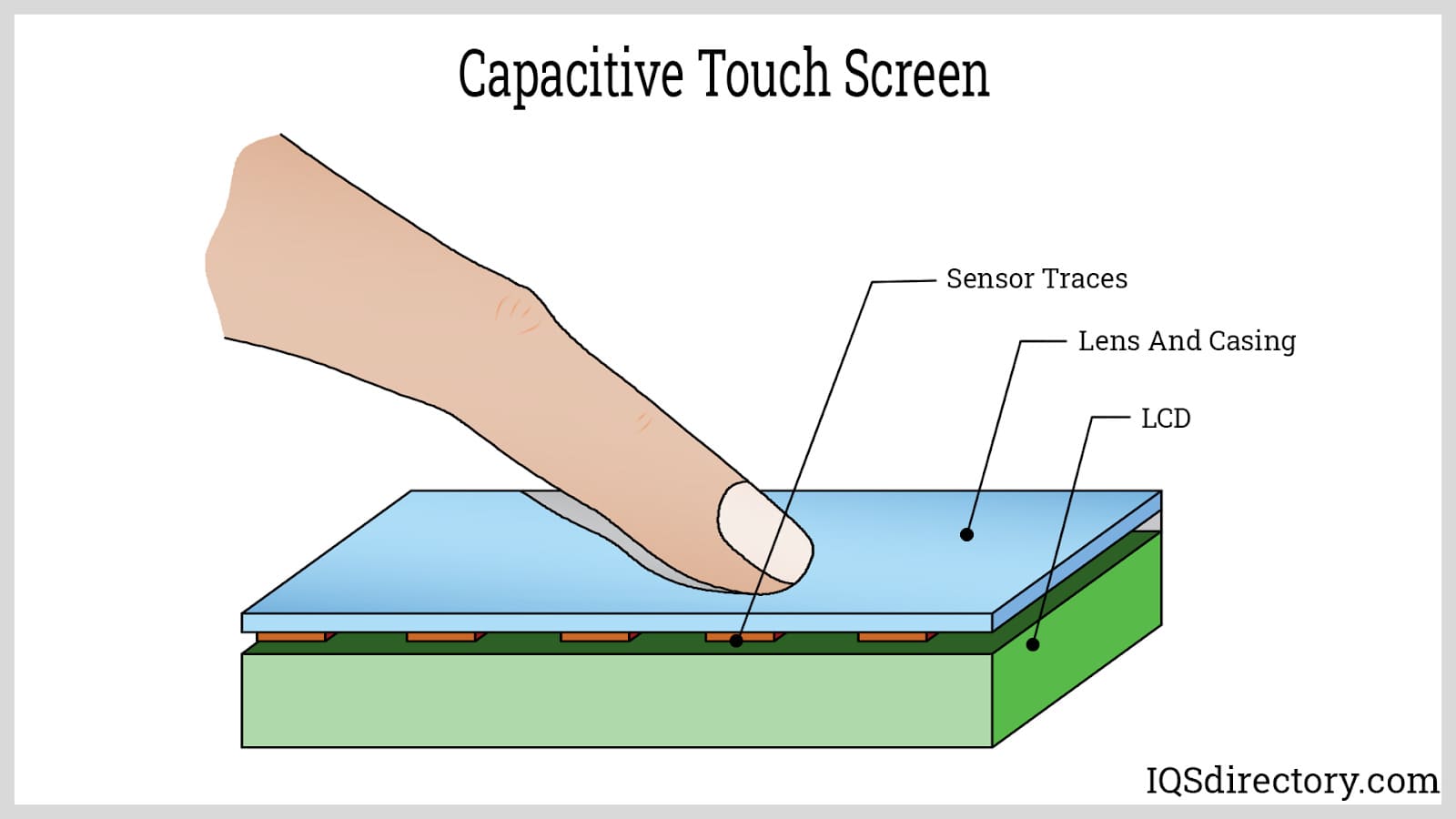

Electrical engineers discovered the many advantages to capacitive coupling technology, which developed into a network of sensors that could be accessed through the use of a conductive stylus, such as a human finger. In essence, this type of touch screen works because the electrical charge from a finger or similar object may access and engage a computer program, allowing various options to be chosen and new options to pop up in response. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

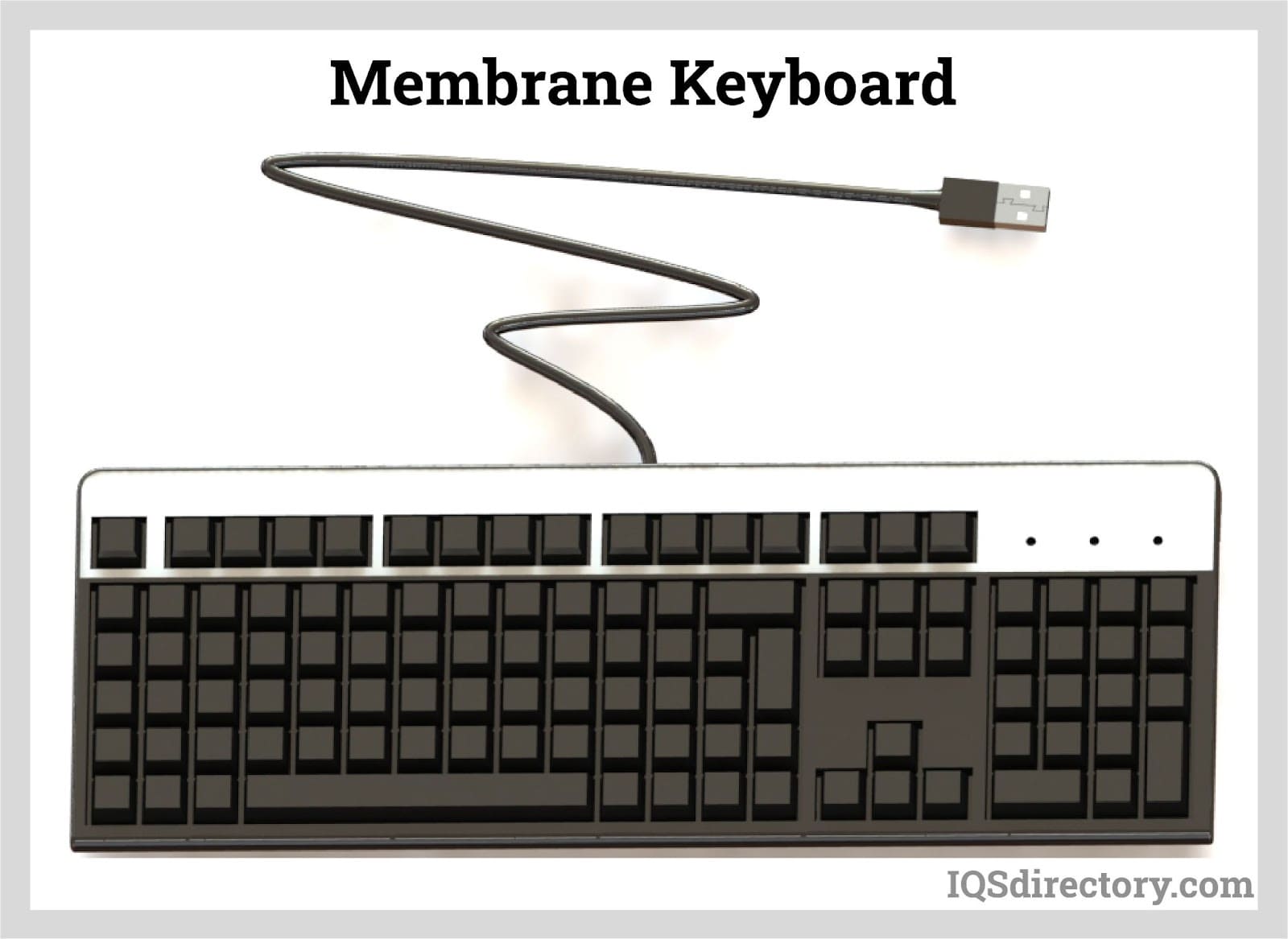

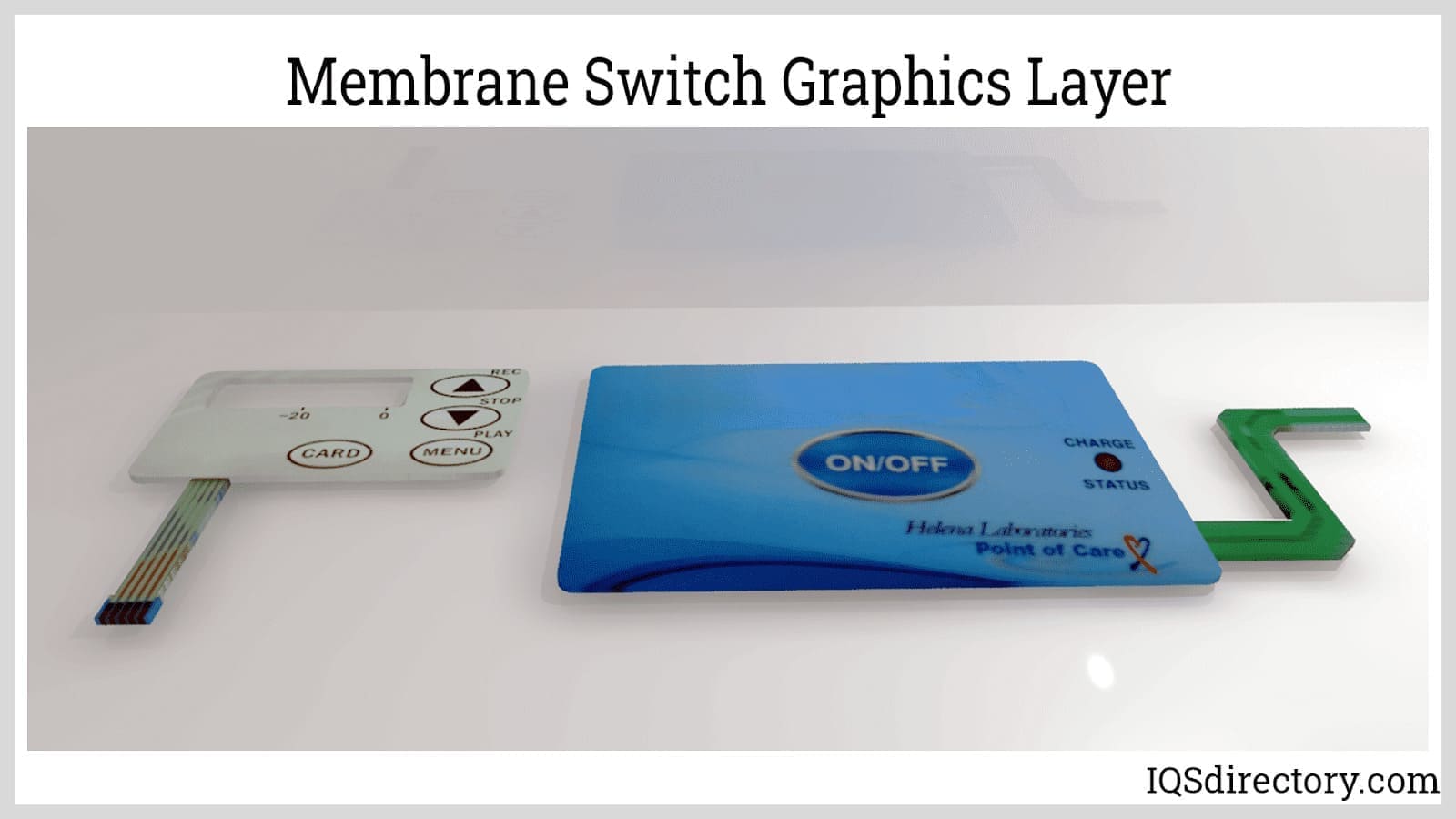

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At Telamco, Inc., we specialize in the design and manufacturing of high-quality membrane switches, providing our clients with robust solutions that meet their diverse needs across a variety of industries. Our products are crafted with precision to deliver durability, reliability, and exceptional performance in environments where control and durability are paramount.

At Cole Graphic Solutions, we specialize in providing high-quality membrane switches designed to meet the unique needs of a variety of industries. With a commitment to excellence, we offer custom solutions that are built to deliver exceptional performance, durability, and precision.

More Capacitive Touch Screen Manufacturers

A basic description of common capacitive touch screen involves surface capacitance, which means that only one side of the product, such as a thick glass screen, is covered with a conductive substance. Other varieties of application are also used, such as the etched conductive layer of projected capacitance.

Certain types of plastic may also be used as the base screen, while the conductive substance is commonly a solution of indium tin oxide; this liquid dries clear when applied in a thin layer while still retaining a high electrical conductivity. Other varieties of coating are also used in capacitive touch screens, although not as often as the liquid already mentioned.

Capacitive touch screens are found in a variety of environments. Banks utilize them for ATM services, enabling individuals to access their accounts and practice transfers, deposits and withdrawals with their fingertips. Many grocery stores now have self check-out lines that utilize capacitive touch screens, allowing customers to purchase objects that can not be self scanned, such as fruit, through interacting with the screen.

These touch screens are also the faces of smartphones, and are therefore being carried through every industrial and commercial setting in the world. Other touch screen technologies are also utilized in today's market, such as resistive touch screens that utilize membrane switches and infrared touch screens. Infrared touch screens employ an x and y axis based program accessed by the breaking of infrared lights through touching the screen.

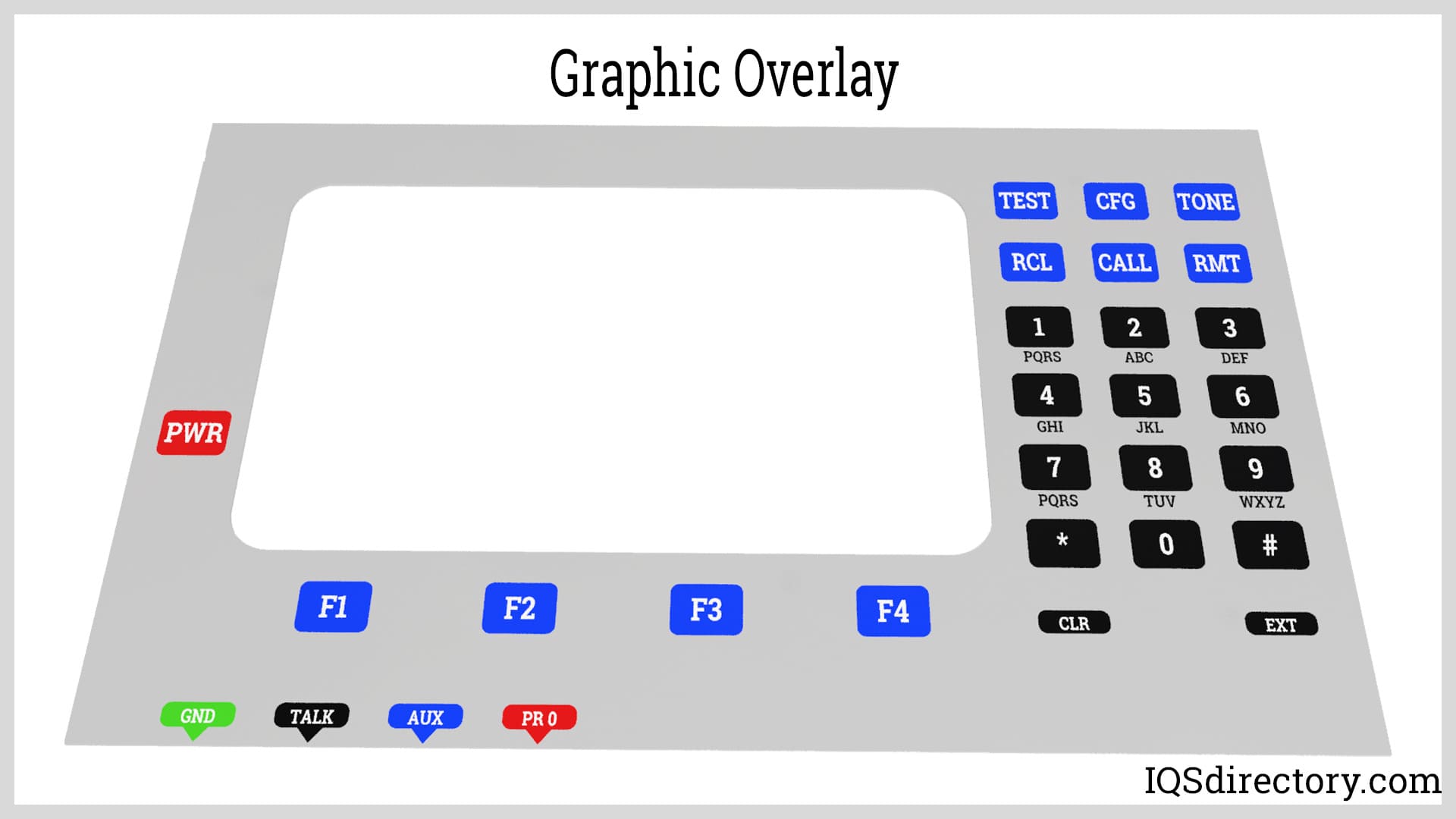

Where on the grid the light is disturbed is processed by way of the x y axis, linking to the next screen or series of options. Touch switches are the membrane switch touch screens that involve pressure to enact the proper response on a screen, since the electrical charge that tells the computer program what to do require two thin metal layers within the screen to connect.

All of these programs have positive and negative qualities, therefore giving touch screen producers many options for production.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services