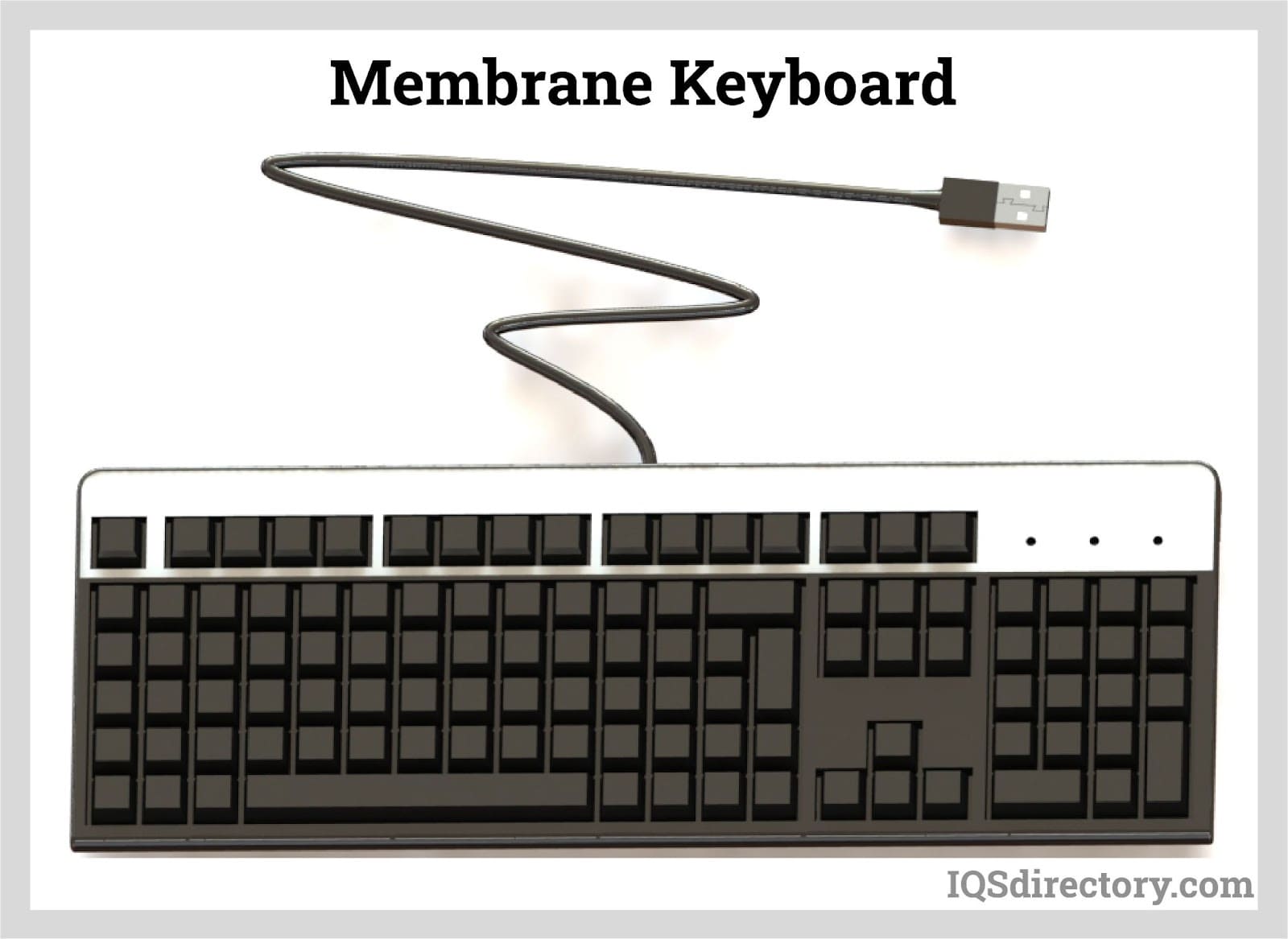

In the context of membrane keyboards, a keyboard switch is composed of a flat, flexible surface and acts as a medium between the keys and the underlying circuits. In the case of tactile switches, they also provide a tactile sensation for the user to indicate a completed keystroke. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At Telamco, Inc., we specialize in the design and manufacturing of high-quality membrane switches, providing our clients with robust solutions that meet their diverse needs across a variety of industries. Our products are crafted with precision to deliver durability, reliability, and exceptional performance in environments where control and durability are paramount.

At Cole Graphic Solutions, we specialize in providing high-quality membrane switches designed to meet the unique needs of a variety of industries. With a commitment to excellence, we offer custom solutions that are built to deliver exceptional performance, durability, and precision.

More Keyboard Switch Manufacturers

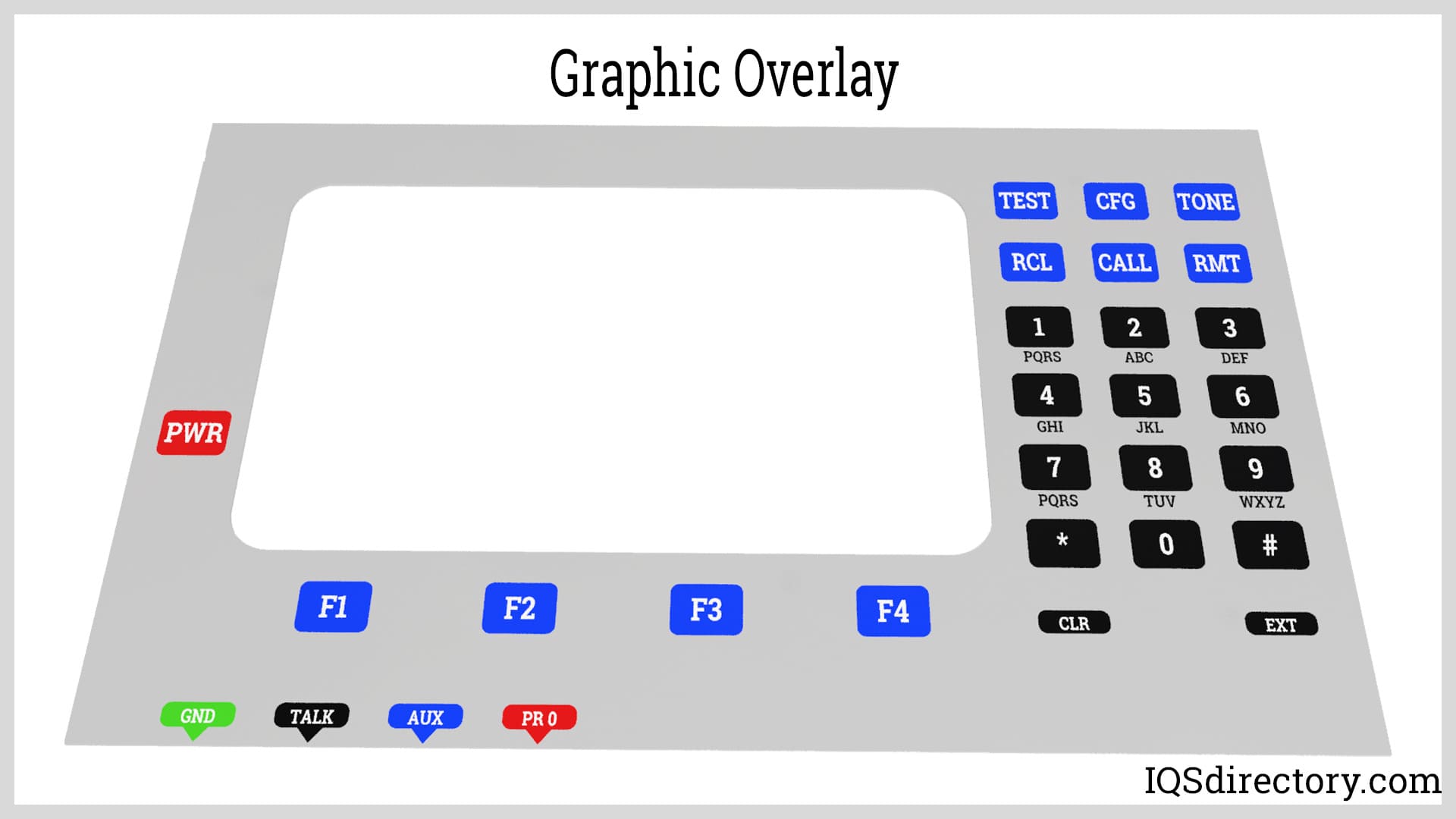

Membrane keyboard switches are fairly inexpensive, easy to mass produce and are resistant to dirt and liquids compared to keyboards that involve many individual keys. Because of their versatility and low cost, membrane keyboard switches are used throughout industry as well as in commercial and consumer products contexts.

In industry, membrane keyboard switches and membrane keypads are used to give commands to manufacturing machinery and service equipment. In commercial settings, telecommunications equipment, commercial cleaners, door access keypads and many other kinds of equipment involve the use of membrane keypads.

Many consumer products are also equipped with keyboard switches; dishwashers, vacuum cleaners, telephones and many other domestic utilities are frequently affixed with keyboard switches.

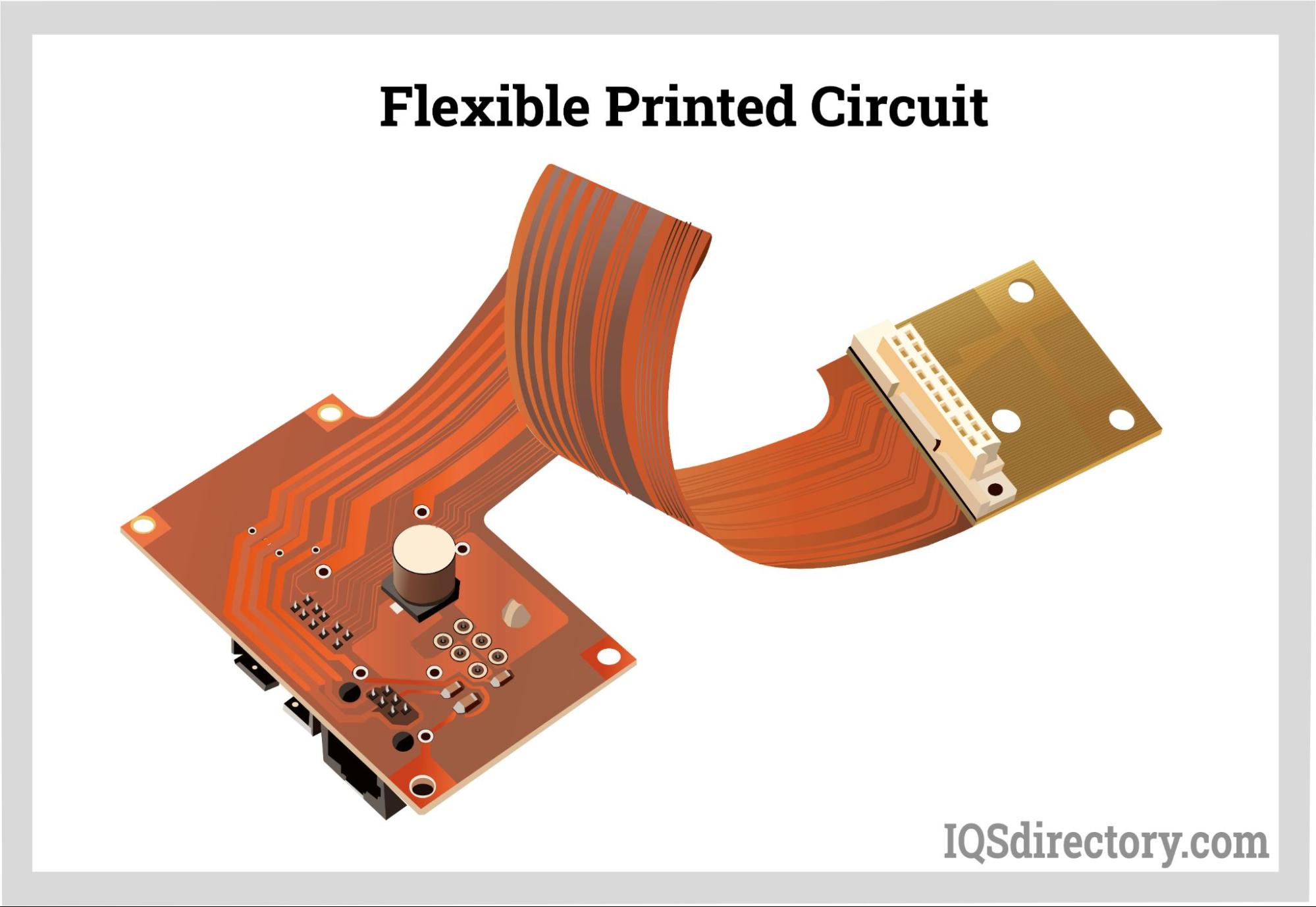

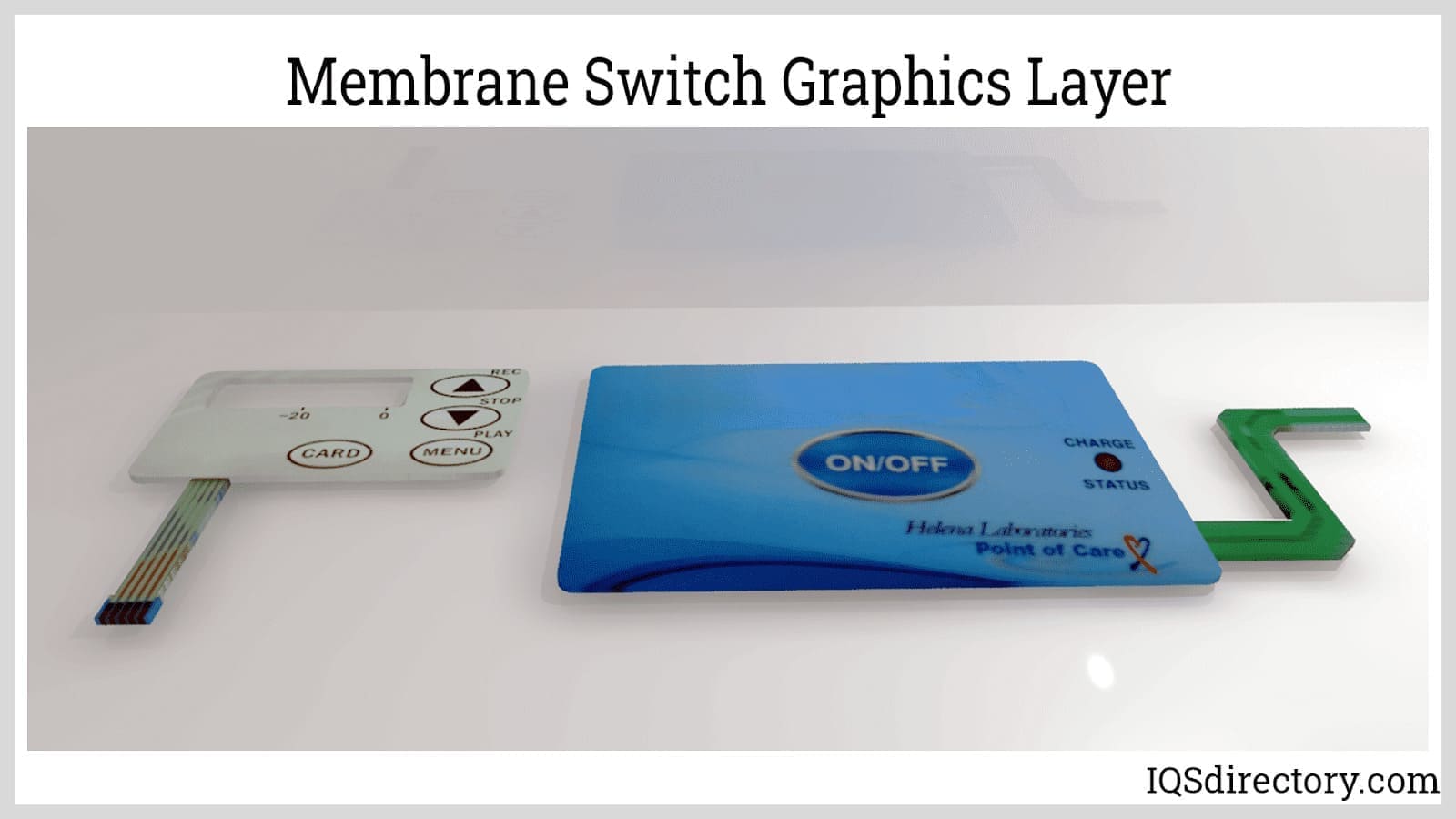

Keyboard switches are either mechanical or non-mechanical and are composed of a variable number of parts, depending on the device's configuration. They most typically are composed of three layers. The bottom layer features the circuitry that connects with the rest of the electrical device. The middle layer serves as insulation, and the top layer features the buttons. Each button is affixed with a discrete, electrically conductive material, which, when forced into contact with the lower circuitry layer, causes the transmission of an electrical signal.

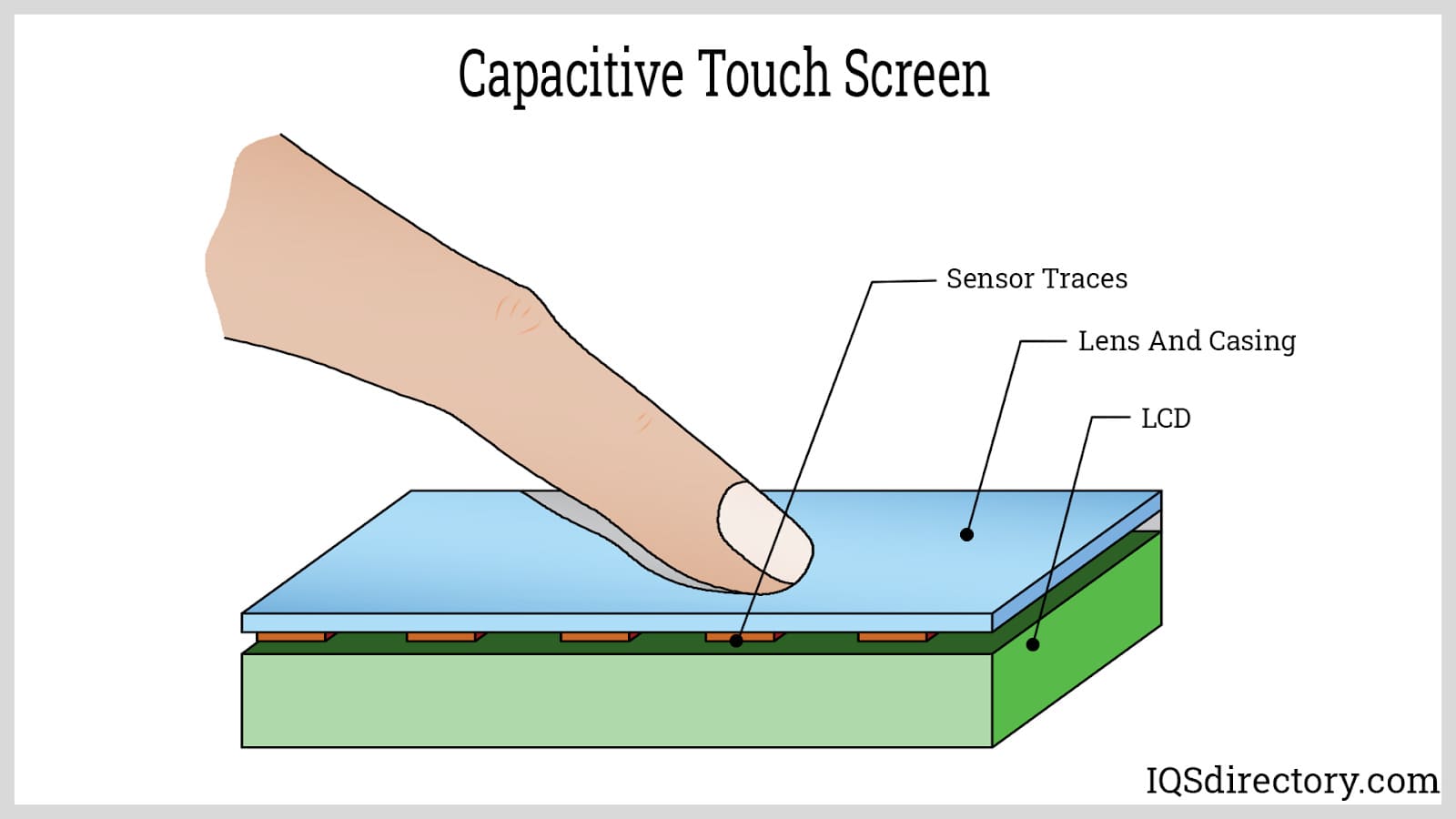

That signal is then processed by the connected electronic device. There are a number of switch technologies that keyboards use. Capacitive switches are non-mechanical because the current is constantly flowing through all parts of the keyboard matrix. The keys are spring-loaded and press down on a metal plate, which touches another plate beneath it to change the current.

The processor detects the change and interprets it as a key stroke for that certain spot. The rest of keyboard switch technologies are mechanical. Dome switches are the most common kind. In this process, the key stroke presses down on a dome beneath the key, which is part of the membrane.

It then connects to a pair of conductive lines and causes electric current to flow. Finally, metal contact switches use spring-loaded keys that are connected to a piece of metal. When pressed, the metal connects with two circuits, which are sometimes made with a foam piece for better tactile response.

Finding the right keyboard switch for a given application is not difficult; a wide variety of configurations are available to meet the needs of the many electronic devices in existence.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services