A rubber keyboard mostly consists of rubber components, making it exceedingly flexible and durable. A rubber keyboard is traditionally created by casting a solid key mat, hiding electrical components under the mat, and fastening a rubber back plate. Some electronics retailers carry these specialized keyboards, and their manufacturers offer them for sale. Several companies also produce rubber keyboards made for laptop use. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At Telamco, Inc., we specialize in the design and manufacturing of high-quality membrane switches, providing our clients with robust solutions that meet their diverse needs across a variety of industries. Our products are crafted with precision to deliver durability, reliability, and exceptional performance in environments where control and durability are paramount.

At Cole Graphic Solutions, we specialize in providing high-quality membrane switches designed to meet the unique needs of a variety of industries. With a commitment to excellence, we offer custom solutions that are built to deliver exceptional performance, durability, and precision.

More Rubber Keyboard Manufacturers

How Rubber Keyboards Operate

Rubber keyboards, also known as silicone rubber keypads or elastomeric keyboards, are essential components in a wide array of electronic devices due to their unique combination of durability, tactile feedback, and design flexibility. The term "silicone rubber keypad" refers to the use of silicone rubber as the primary material for their webbing and keys. Unlike traditional hard plastic keyboards or membrane keypads, rubber keypads offer a soft, responsive touch and enhanced protection for underlying circuit components.

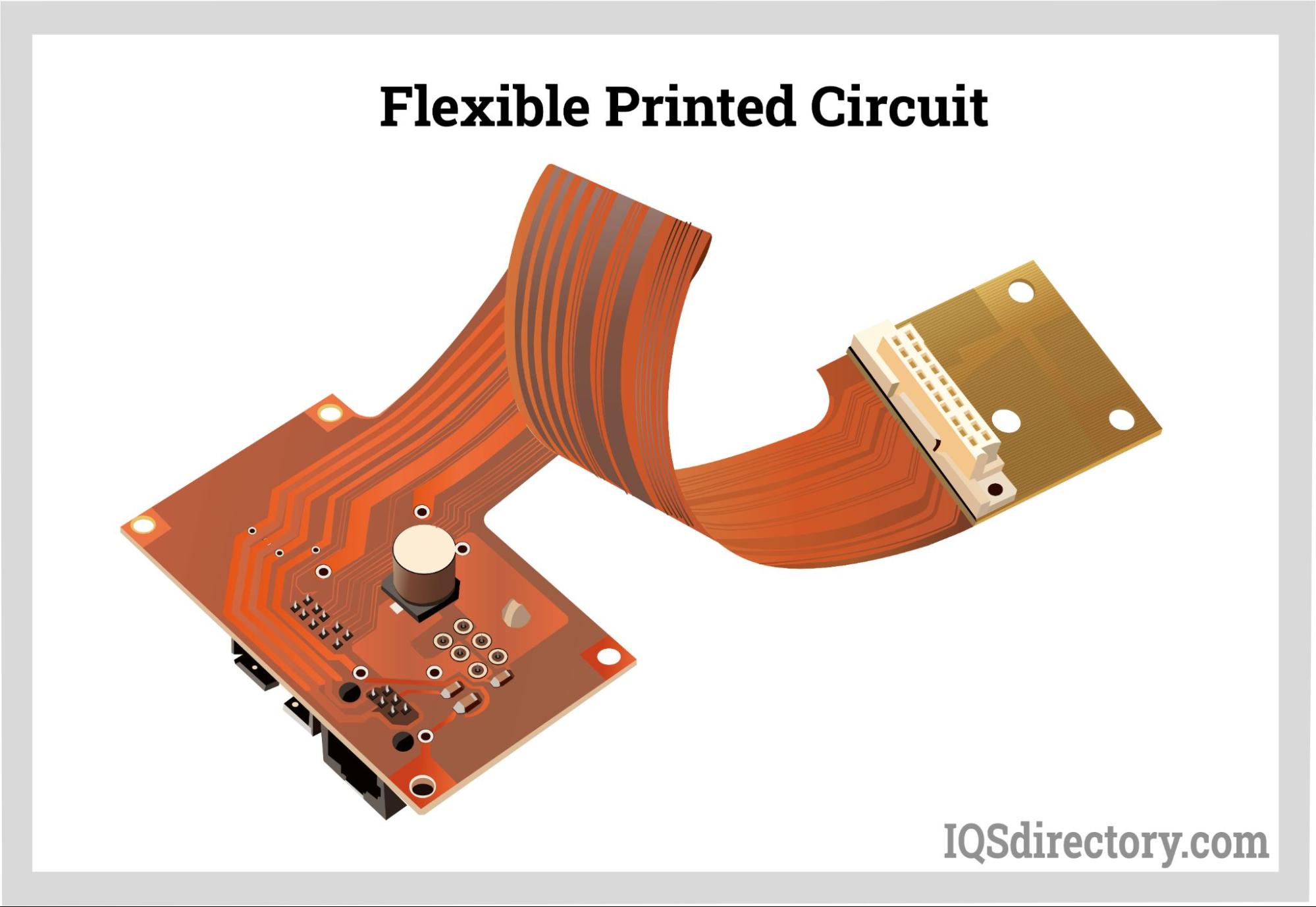

The construction of a typical silicone rubber keypad involves a raised switch encased in a flexible silicone rubber webbing. Beneath each key sits a conductive pill, commonly made of carbon or gold. When a key is pressed, the webbing compresses, bringing the conductive pill into contact with the traces on a printed circuit board (PCB). This completes the circuit and sends the signal required to operate the connected device. The use of silicone rubber provides natural tactile feedback—when a key is pressed and then released, the material’s elasticity causes it to spring back to its original position, delivering a satisfying “pop” or click that users expect from high-quality keypads.

The effectiveness of silicone-rubber keypads is largely due to their unique cross-section. Most designs feature a dome-shaped web of silicone surrounding each switch. The underside of the dome is coated with a conductive material (carbon or gold), which sits above a corresponding switch contact on the PCB. Between the dome and the contact is a pocket of air or inert gas, ensuring reliable actuation and electrical isolation when the key is not pressed.

This innovative structure allows for excellent tactile response and long-term reliability. Silicone’s inherent compression molding capabilities make it possible to create intricate key shapes, custom legends, and even backlighting features. As a result, rubber keypads are commonly found in applications requiring frequent use, moisture resistance, and custom design flexibility.

How Rubber Keyboards are Made

Rubber keyboards and silicone keypads are produced using a process called compression molding. This method allows manufacturers to create precise, durable, and highly customizable keypads suited for a wide range of electronics, from industrial controls to medical devices.

In compression molding, raw silicone is placed into a specialized mold, which consists of two metal halves designed to form the desired keypad shape. Think of this mold like a waffle iron, but instead of making waffles, it creates the intricate patterns and contours of a rubber keypad. The lower half of the mold contains the negative impression of the keypad's design, while the upper half completes the cavity, ensuring the silicone fills every detail.

The process involves several key steps:

- Loading the mold cavities with the appropriate amount and color of silicone rubber compound, which can be customized for hardness, color, and additional features like luminescence or antimicrobial properties.

- Closing the mold and applying heat and pressure, typically between 150°C to 180°C, for a specific period. This causes the silicone to flow and cure, taking on the shape of the mold and forming a solid, resilient keypad.

- Once cured, the mold opens, and the finished keypads are carefully removed. Secondary processes such as laser etching, graphic printing, or the application of coatings (like polyurethane for improved abrasion resistance) may be performed to add legends, symbols, or further enhance durability and aesthetics.

Advanced manufacturing techniques allow for additional features such as backlighting (via light pipes or translucent silicone), multicolor legends, and integrated sealing for water and dust resistance. These capabilities make rubber keypads an attractive solution for industries with demanding operational environments, such as automotive, marine, industrial automation, medical, and consumer electronics.

Advantages of Rubber Keyboards

Choosing a rubber keyboard or silicone rubber keypad offers a range of benefits that cater to diverse industries and user requirements. Whether you’re evaluating input solutions for industrial control panels, medical devices, or rugged consumer electronics, rubber keypads deliver exceptional versatility, resilience, and user experience.

- Flexibility and Portability: One of the main advantages of a rubber keyboard is its flexibility. These flexible keyboards can be rolled up and easily transported in a bag or briefcase without the risk of damage or sharp edges. This makes them ideal for mobile professionals, field technicians, and anyone needing a full-sized keyboard on the go. Flexible rubber keyboards are especially popular as portable accessories for laptops, tablets, and other handheld devices.

- Spill and Environmental Resistance: Many rubber keyboards are waterproof or spill-resistant, making them suitable for use in challenging environments. This feature is essential for outdoor applications, industrial settings, kitchens, or medical environments where exposure to liquids, dust, or contaminants is common. Some models are even rated for underwater use or harsh weather conditions.

- Durability and Impact Resistance: Rubber keypads are designed to withstand heavy use and abuse, making them ideal for users with a forceful typing style or applications where the device is exposed to vibration, shock, or regular cleaning. The elastic nature of silicone rubber ensures the keys remain intact and functional even after millions of actuations.

- Low Noise Operation: Silicone rubber keypads can be engineered for quiet keystrokes, making them perfect for noise-sensitive environments such as hospitals, offices, or control rooms. The soft, cushion-like feel reduces audible feedback while maintaining tactile response.

- Ergonomic Comfort: Comfort is a critical factor when selecting a keypad. Rubber keypads offer a soft, smooth, and ergonomic touch, reducing strain during prolonged use. Their natural elasticity and customizable actuation force allow for a tailored typing experience that can be optimized based on user preference.

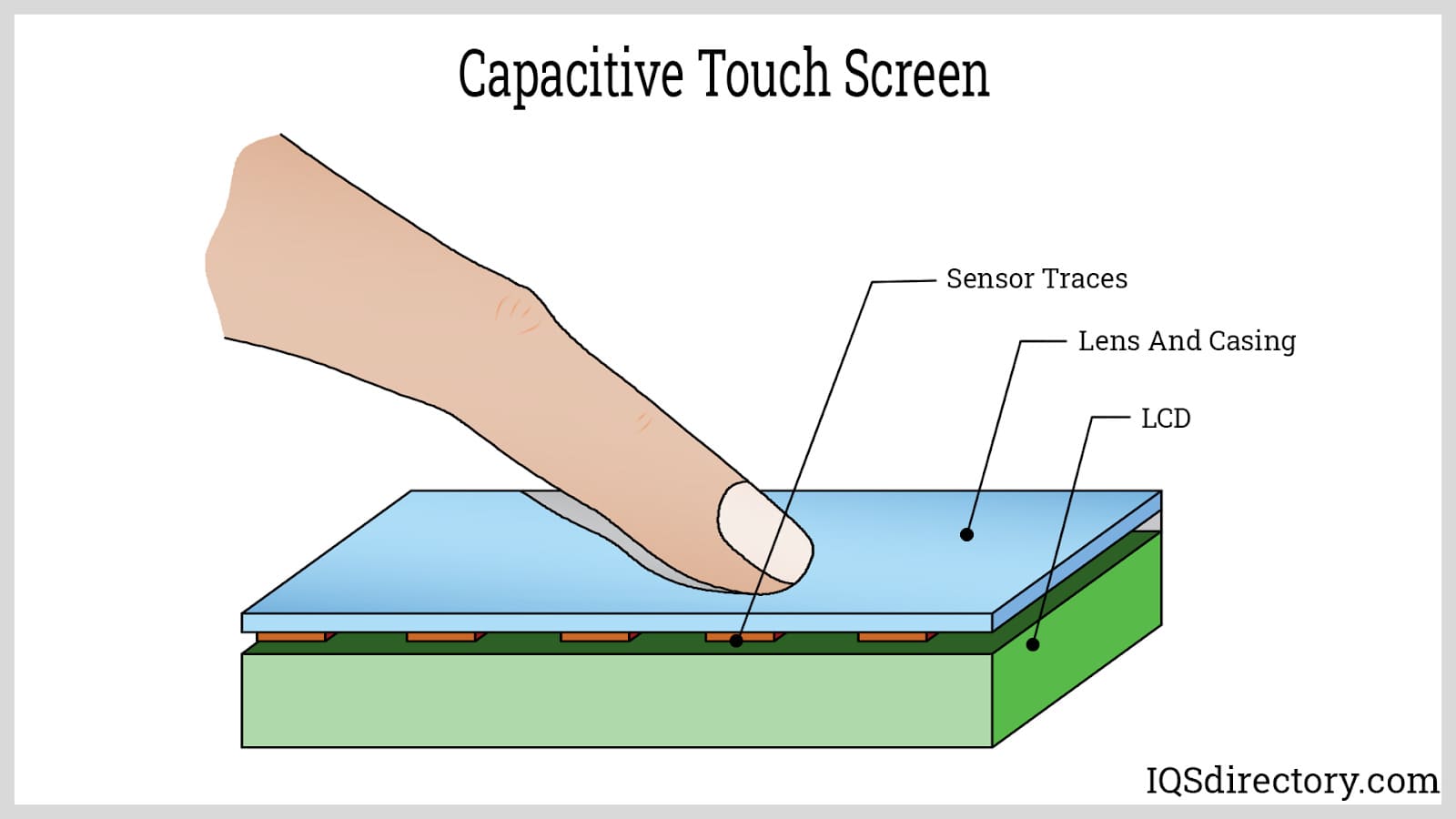

- Cost-Effectiveness and Scalability: Compared to other input technologies like mechanical switches or capacitive touchscreens, silicone rubber keypads are typically more affordable to produce, especially for custom designs and high-volume orders. Their cost-effectiveness allows manufacturers to integrate them into a wide range of devices without inflating the final product price.

- Design Versatility: With compression molding, manufacturers can create custom shapes, colors, legends, and even incorporate branding elements or multi-language layouts. Options such as backlighting, tactile feedback, and integrated sealing further increase the versatility of rubber keypads for specialized applications.

- Sealing and Protection: Rubber keyboards can be designed with integrated seals to achieve IP65, IP67, or higher ingress protection ratings, shielding sensitive electronics from water, dust, and chemicals. This is essential for medical devices, outdoor controls, and marine equipment.

Common Applications of Rubber Keypads

Wondering where rubber keyboards and silicone keypads are most often used? Their unique combination of durability, tactile feedback, and design flexibility makes them the preferred choice for a variety of industries and devices, including:

- Medical Equipment: Rubber keypads are ideal for hospital devices, patient monitoring systems, and diagnostic equipment due to their ease of cleaning, resistance to harsh chemicals, and ability to withstand frequent sterilization.

- Industrial Controls: In factory automation, robotics, and heavy machinery, silicone keypads offer reliable performance in environments with dust, moisture, and vibration.

- Consumer Electronics: From remote controls and calculators to handheld gaming consoles, rubber keypads provide a comfortable and responsive user interface.

- Marine and Outdoor Devices: Their waterproof and UV-resistant properties make them suitable for navigation equipment, communication devices, and outdoor instrumentation.

- Automotive Controls: Used in dashboard controls, keyless entry systems, and infotainment units where long lifespan and tactile feedback are important.

- Telecommunications: Landline phones, two-way radios, and intercoms frequently use silicone keypads for their durability and ease of customization.

- Point-of-Sale (POS) Terminals: Retail and payment devices benefit from the robust and reliable input provided by rubber keypads.

- Fitness and Wearable Devices: Compact form factors and sweat-resistance make them suitable for sports watches and fitness trackers.

Are Rubber Keypads Right for Your Project?

If you’re considering input options for your next electronic device, ask yourself:

- Do you need a durable, waterproof, or dustproof interface for demanding environments?

- Is tactile feedback and ergonomic comfort a priority for your users?

- Does your application require custom legends, shapes, or backlighting?

- Are size, cost, and ease of integration important design factors?

If you answered yes to any of these questions, a silicone rubber keypad could be the ideal solution for your needs. To explore more, discover our guide to custom silicone keypads or compare leading rubber keyboard suppliers now.

Decision Factors: What to Look for When Buying Rubber Keyboards

Selecting the right rubber keyboard or elastomeric keypad involves more than just price. To maximize the reliability and performance of your device, consider these important factors during your supplier evaluation:

- Material Quality: Look for keypads manufactured from medical-grade or industrial-grade silicone for superior longevity, chemical resistance, and UV stability.

- Customization Options: Does the supplier offer options for custom shapes, colors, legends, multi-language layouts, or backlighting? Tailoring the design can significantly enhance the usability and brand identity of your device.

- Electrical Performance: Ensure the conductive materials (carbon, gold, or silver) provide consistent actuation force and low electrical resistance. Ask about life-cycle testing and electrical reliability data.

- Environmental Ratings: For outdoor, medical, or industrial applications, verify the keypad meets the required ingress protection (IP) ratings for water, dust, and chemical resistance.

- Tactile Feedback: Consider whether your application requires a soft touch, firm response, or audible click. Some suppliers can customize the tactile feel to suit your preferences.

- Certifications and Compliance: For regulated industries, confirm that the supplier’s products are compliant with standards like RoHS, REACH, UL, or FDA.

- Lead Time and Production Capacity: Evaluate the supplier’s ability to handle your preferred order volume and meet your project timelines.

- After-Sales Support: Does the company offer engineering support, samples, prototyping, and warranty coverage?

Need help comparing rubber keyboard vendors? Use our search-style prompt: “Which rubber keyboard supplier offers the best combination of cost, customization, and delivery time for my application?” or “How can I select a silicone keypad manufacturer that meets my industry standards?”

Choosing the Proper Rubber Keyboard Supplier

To ensure a successful sourcing experience when purchasing rubber keyboards or custom silicone keypads, it’s crucial to compare multiple manufacturers. Here are some actionable steps to help you make an informed purchase decision:

- Research and Compare: Start by reviewing at least 4 companies from our curated list of rubber keyboard manufacturers. Examine each supplier’s business profile, manufacturing capabilities, certifications, and customer reviews.

- Request Quotes: Use our simple RFQ (Request for Quote) form to contact multiple suppliers simultaneously. Clearly outline your technical requirements, volume estimates, and delivery timelines to ensure accurate pricing and lead time information.

- Evaluate Product Samples: Request engineering samples or prototypes to verify material quality, tactile feel, and fit with your device enclosure. Testing real samples can uncover issues not evident from datasheets alone.

- Check Website and Capabilities: Use our proprietary website previewer to quickly assess each company’s specialties, such as custom backlighting, laser etching, or high-volume production.

- Direct Communication: Utilize the contact form provided on each supplier’s profile to ask technical questions, clarify certifications, or discuss design customization. Effective communication ensures your expectations are clearly understood and met.

Buyer’s Tip: Always request official datasheets, environmental test results, and references from previous clients in your industry. This helps verify the credibility and reliability of your chosen supplier.

Interested in exploring more? Try asking: “What are the latest advancements in silicone rubber keypad technology?” or “Which rubber keyboard features are best for harsh environments?”

Frequently Asked Questions About Rubber Keyboards

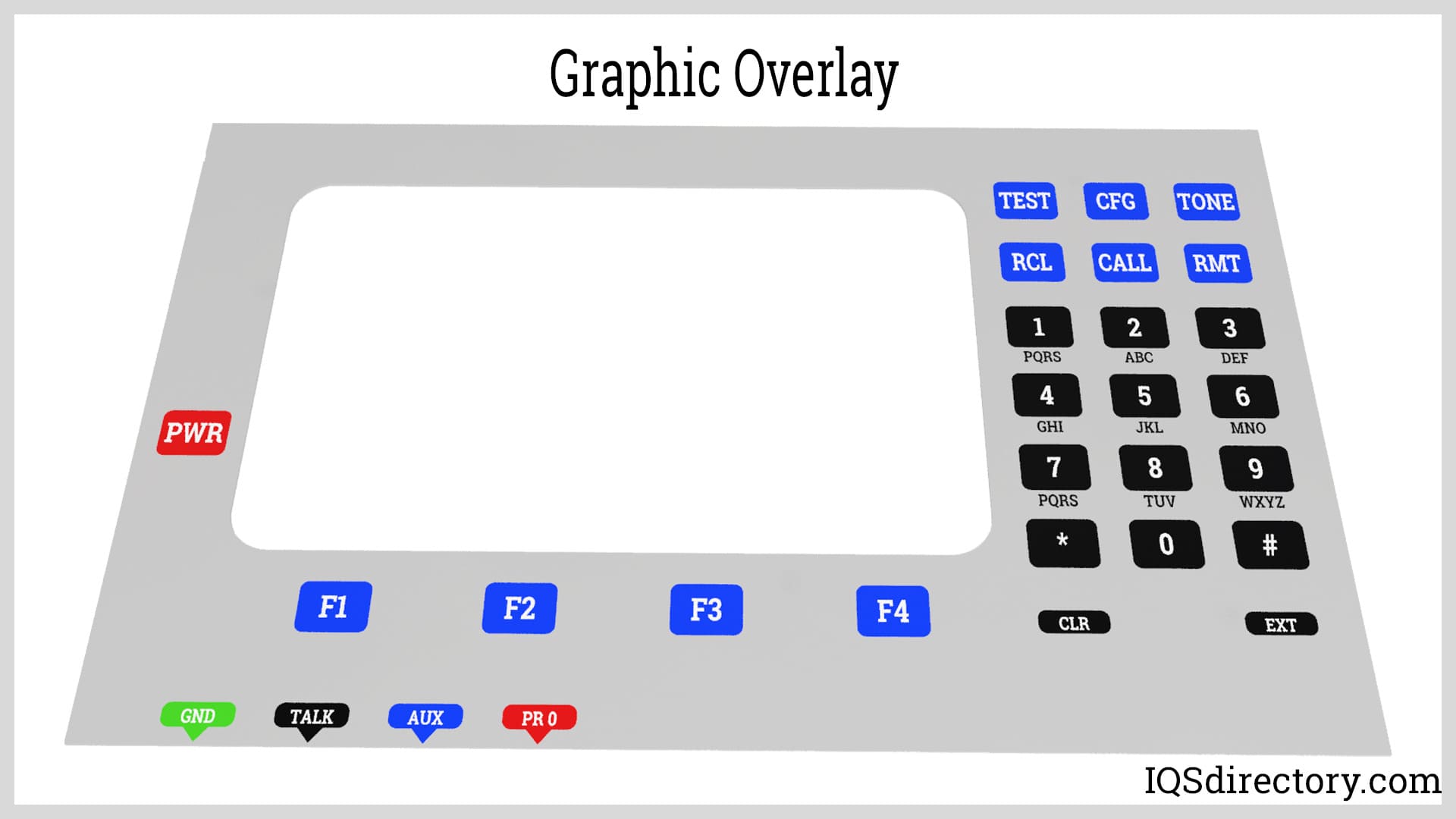

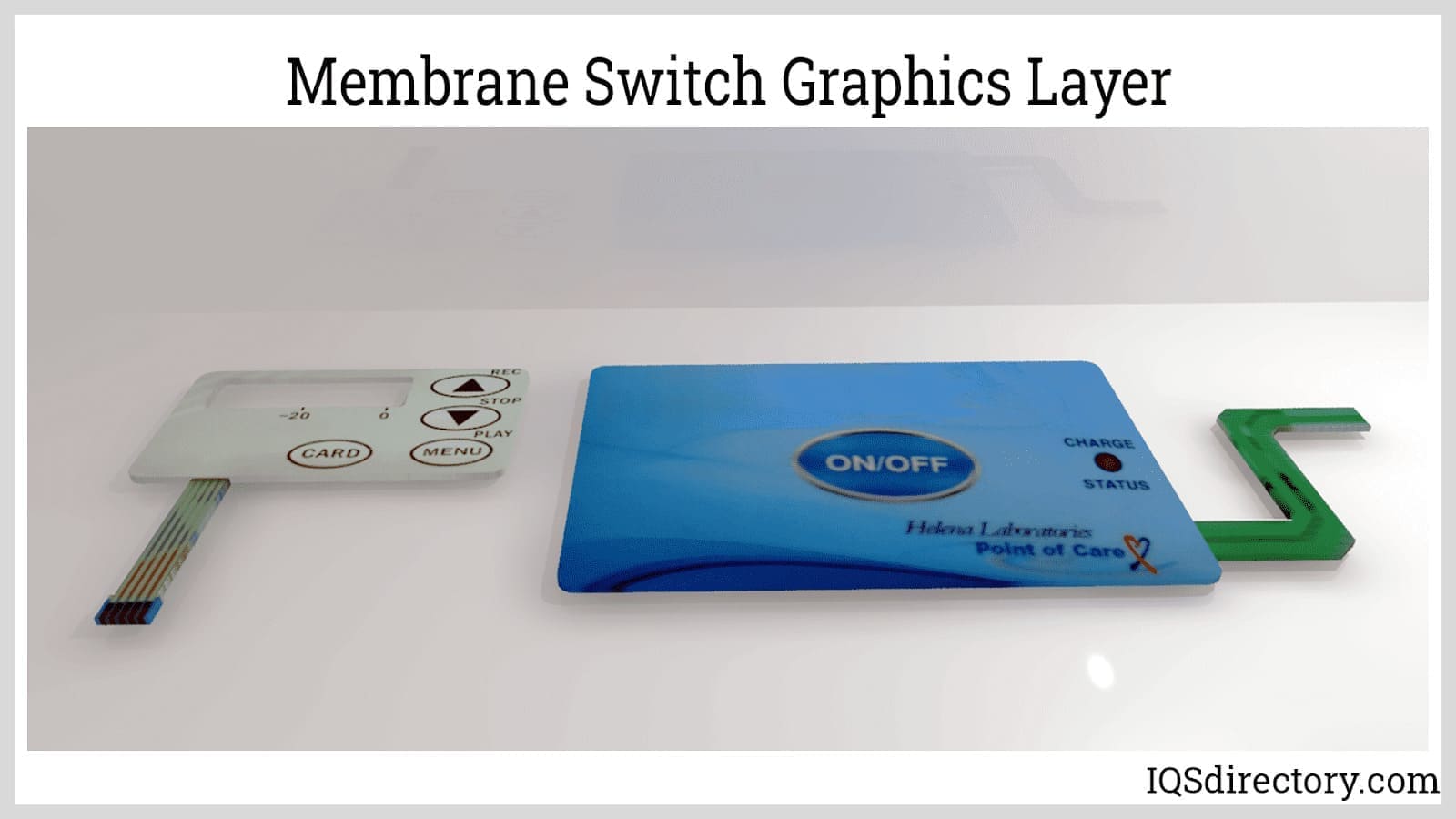

What is the difference between rubber keypads and membrane switches?

While both rubber keypads and membrane switches are popular input solutions, they differ in construction and tactile feel. Rubber keypads use molded silicone with individual keys, offering a soft and tactile response. In contrast, membrane switches are typically flat, using printed circuits and flexible layers, resulting in a thinner profile but less pronounced tactile feedback. If your application demands comfort, custom shapes, or rugged sealing, rubber keypads are often the superior choice.

How durable are silicone rubber keypads?

Silicone rubber keypads are engineered for extreme durability. Many models are rated for millions of actuations and can withstand exposure to chemicals, UV light, moisture, and temperature fluctuations. Their resilience makes them ideal for mission-critical medical devices, outdoor equipment, and industrial machinery.

Can rubber keyboards be customized for branding or unique layouts?

Yes! One of the primary advantages of compression-molded rubber keypads is their high degree of customization. Manufacturers can create unique shapes, custom legends, multicolor printing, backlighting, and branding elements to match your company’s specifications and enhance your product’s appeal.

Are rubber keyboards suitable for medical or food-grade applications?

Absolutely. Medical-grade silicone is available for applications where compliance with hygiene and safety regulations is required. These keypads are easy to clean, resistant to disinfectants, and can be designed to withstand repeated sterilization cycles.

How do I maintain and clean a rubber keyboard?

Rubber keyboards are simple to maintain. They can be wiped down with mild soap and water, or disinfectant wipes, without risking damage to the keys or circuitry. For devices exposed to harsh chemicals or extreme environments, choose keypads with a protective coating or sealed surface.

Ready to Find the Perfect Rubber Keyboard?

Whether you need a custom silicone keypad for industrial automation, a waterproof input solution for marine electronics, or an ergonomic keyboard for medical devices, rubber keypads deliver unmatched performance, value, and design flexibility. Explore our complete directory of rubber keyboard manufacturers, compare features, and request a quote today to optimize your next project.

Start your search now:

“Who are the leading suppliers of custom rubber keyboards for industrial applications?”

“How do I select the most durable silicone keypads for my medical device?”

“What are the latest trends in flexible and waterproof keyboard design?”

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services